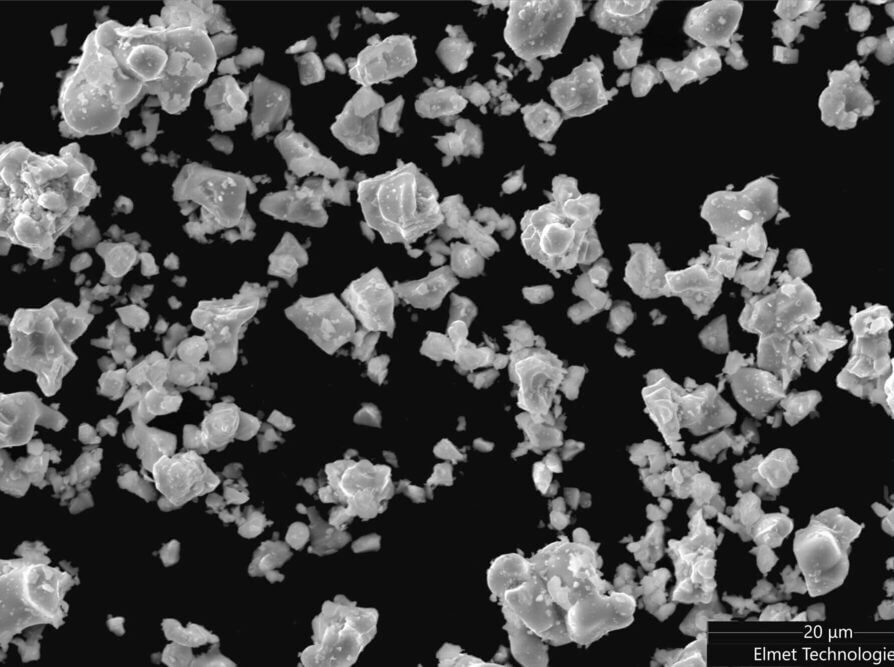

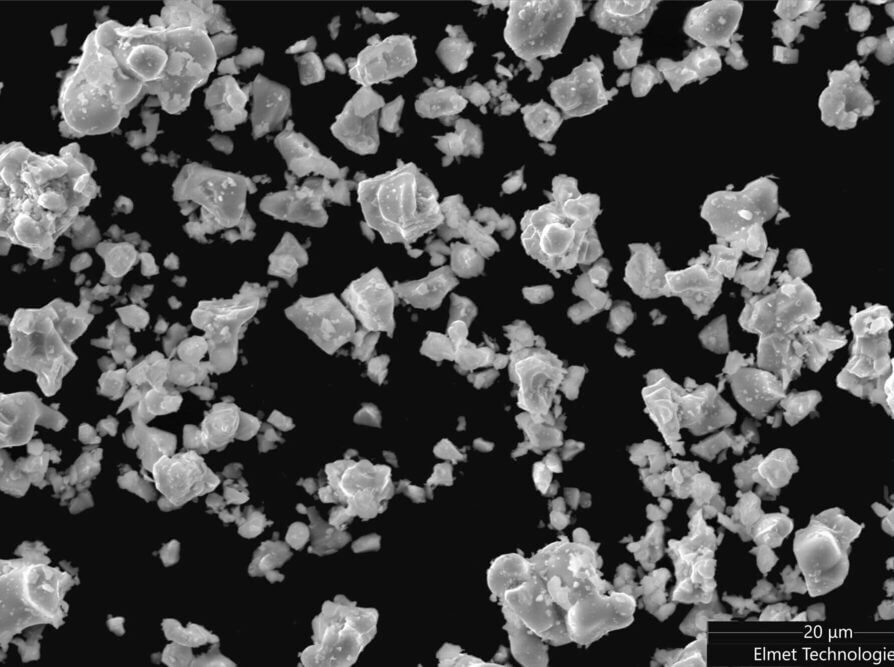

Zirconium Carbide Powder

Elmet Technologies is a trusted source for zirconium carbide powder, available in both Grade A and Grade B classifications. This high-performance transition metal powder, characterized by its gray metallic color and cubic system structure, offers outstanding properties such as high wear and corrosion resistance and a very high melting point. These features make zirconium carbide (ZrC) powder an ideal material choice for various thermal surfacing techniques.

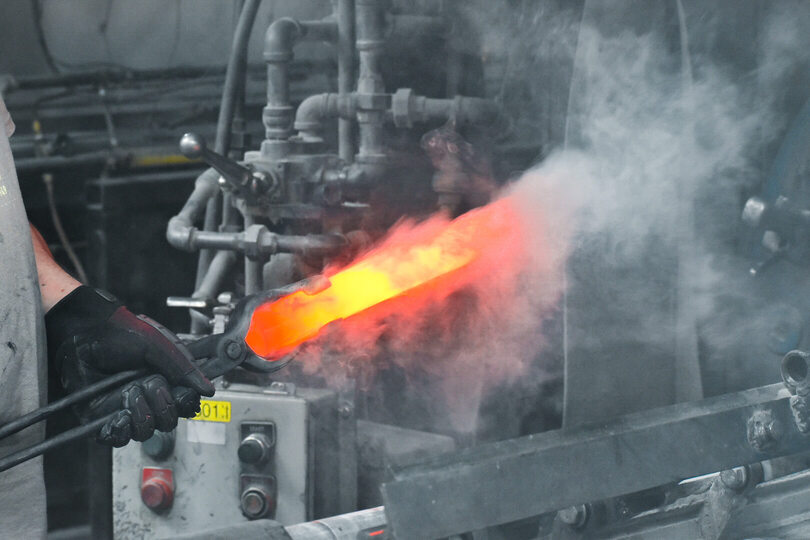

ZrC enhances processes like powder welding, oxyacetylene spraying, HVOF/HAFA spraying, plasma transferred arc overlaying, plasma spraying, laser overlaying, and induction melting overlaying. We prioritize performance and reliability in every product we offer, including the highly-regarded zirconium carbide powder.

High-Quality Zirconium Carbide Powder

Zirconium carbide powder is an exceptionally hard, refractory ceramic material. Produced as a byproduct of titanium and tin mining, this transition-metal powder has numerous applications, including use as an opacifier and refractory material.

At Elmet Technologies, we source zirconium carbide powder from dependable suppliers. We excel in manufacturing zirconium carbide powder to meet all MIL specifications, and welcome custom inquiries to cater to your unique requirements.

Properties of ZRC Powder

Chemical Properties

Mass fraction in % [cg/g]; ppm [µg])

| Grade A | Grade B | |

|---|---|---|

| Zr + Hf | 87.8% min | 87.4% min |

| Hf | 2% max | 2% max |

| C total | 11.4% min | 10.8% min |

| C bound | 11% min | 9.5% min |

| C free | 0.4% max | 1.5% max |

| Fe | 0.05% max | 0.05% max |

| O | 0.6% max | 0.6% max |

| N | 0.8% max | 0.8% max |

Physical Characteristics

Particle size distribution

| Grade A | Grade B | |

|---|---|---|

| D 10% | 2-4 | 1-3 |

| D 50% | 5-13 | 3-5 |

| D 90% | 11-35 | 8-12 |

Benefits of Zirconium Carbide Powder

- Corrosive resistant

- Strong thermal and electrical conductivity

- High melting point

- High elastic modulus

- High hardness

- Low density

- Stable for a carbon-to-metal ratio ranging from 0.65 to 0.98

- Practically Inert to strong aqueous acids

Key Applications for Improved Performance

Enhances thermal surfacing techniques like powder welding, flame spraying, plasma spraying, and high velocity oxy-fuel, which provides superior surface protection and exceptional wear resistance.

Plays a key role in industries like oil exploration, aerospace, mining, manufacturing, and marine operations. ZrC’s versatility boosts extraction, improves machinery, and supports advanced engineering.

Amplifies the durability of wear-resistant parts and components, including feed screws, aero-engines, fan blades, turbine blades, pump cases, and cutting tools, ensuring longevity and efficiency.

Widely utilized in the steel industry, it actively enhances cutting tool performance. When used as an additive, it refines WC cemented carbide crystals, significantly enhancing alloy properties.

Performance Starts with Powder

Since 1929, Elmet Technologies has proudly sustained a tradition of producing superior, U.S.-manufactured metal powder solutions for industries requiring precision and durability. Specializing in refractory metals, we provide an extensive range of products such as tungsten (W) and molybdenum (Mo), as well as advanced alloys including TZM, MoLa, MoTa, WHA, WK, HCT, and more. Our dedicated team manufactures all our products in the USA.

By utilizing innovative processing capabilities, we deliver customized solutions that meet the most stringent specifications. Elmet’s commitment to U.S. manufacturing guarantees that every product embodies the highest standards of quality, reliability, and innovation.