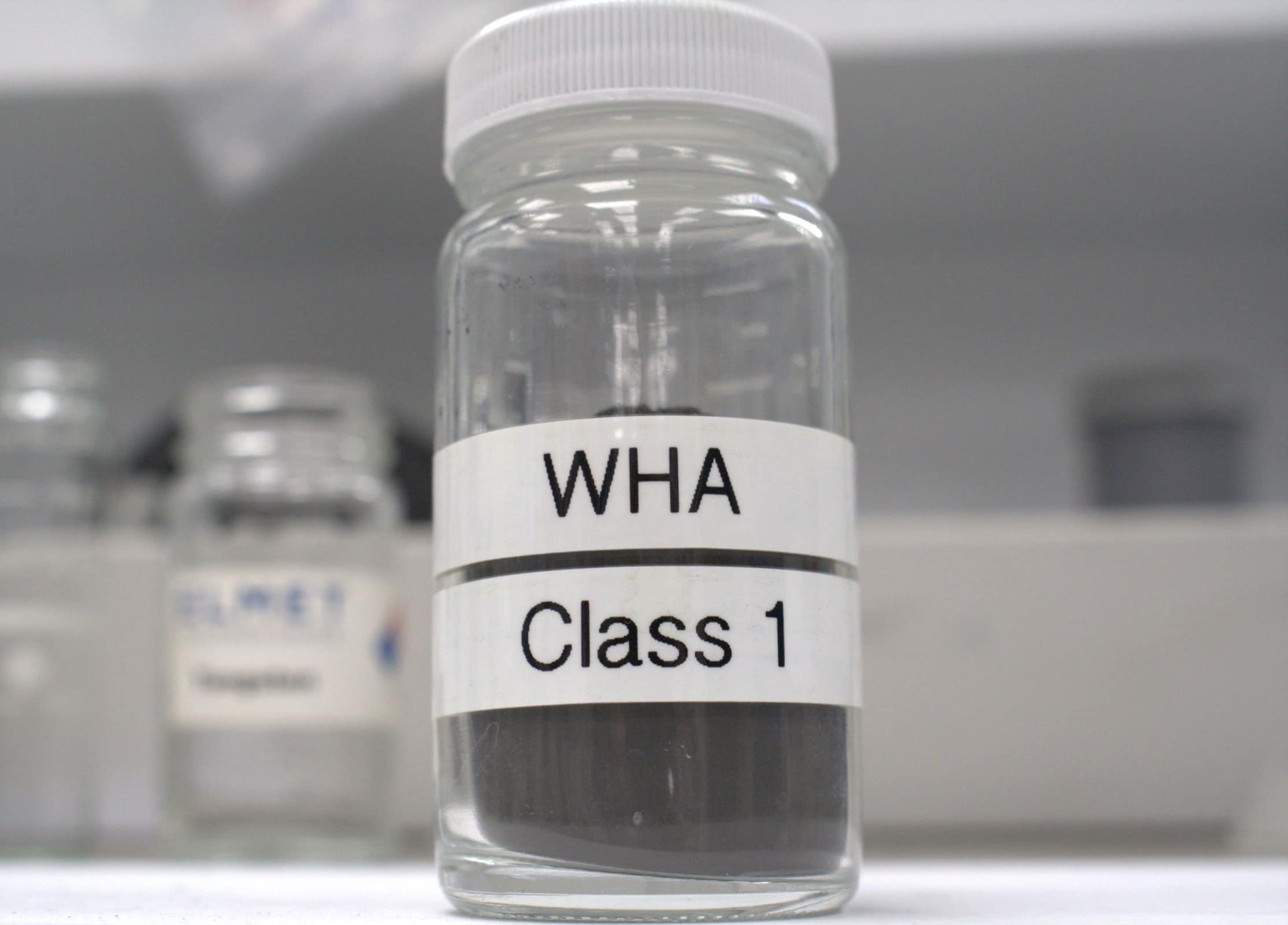

ASTM B777 Class 1 Powder

Elmet Technologies manufactures ASTM B777 Class 1 Powder, one of four classes defined in standard specifications for tungsten base metal. Class 1 is distinguished by its lowest tungsten content, providing exceptional ductility and ease of machining. This alloy is composed of pure tungsten combined with a binder of nickel (Ni) and iron (Fe). In addition to Class 1 Powder, Elmet Technologies also manufactures ASTM B777 Class 2, 3, and 4 powders.

When pressed, sintered, and machined, Class 1 WHA powder forms a high-quality tungsten heavy alloy with the lowest density among the four ASTM B777 classes. Despite its lighter density, it remains over twice as dense as steels and most nickel-based superalloys, ensuring strength and durability for a wide range of demanding applications.

Benefits of ASTM Class 1 WHA Powder

- Superior Radiation Shielding: Provides an eco-friendly, high-density alternative to lead, excelling in radiation shielding applications.

- Vibration Dampening & Balancing: Delivers exceptional performance in vibration dampening and balance weight solutions.

- Unmatched Density: Perfectly suited for applications demanding extremely high density.

- Effective Radiation Absorption: Absorbs gamma rays and X-rays with outstanding efficiency.

- Enhanced Machinability: Offers improved machinability compared to pure tungsten, simplifying production processes.

- Exceptional Mechanical Properties: Boasts excellent strength and durability for demanding applications.

Technical Data & SPecifications

| Grade | Units | K1700 | ET90 | K1701 | ET90NM |

| Tungsten content, Nominal | % | 90 | 90 |

| Density, Nominal | (g/cm3) | 17.0 | 17.0 |

| (lb/in3) | 0.61 | 0.61 | |

| Hardness | (Rc) | ≤ 32 | ≤ 32 |

| Ultimate Tensile Strength | (ksi) | ≥ 110 | ≥ 94 |

| (N/mm2) = Mpa | ≥ 758 | ≥ 648 | |

| Yield Strength | (ksi) | ≥ 75 | ≥ 75 |

| (N/mm2) = Mpa | ≥ 517 | ≥ 517 | |

| Elongation | (%) | ≥ 5 | ≥ 2 |

| Modulus of Elasticity | (psi x 106) | 45 | 40 |

| (kN/mm2) | 310 | 280 | |

| Magnetic Properties | slight | none | |

| Magnetic Permeability | (µ) | > 1.05 | ≤ 1.05 |

| Thermal Expansion Coefficient | (x10-6/K)(20°C-500°C) | 5.1 | 5.4 |

| Thermal Conductivity | (cgs) | 0.2 | 0.23 |

| Electrical Conductivity | (% IACS) | 11 | 14 |

| AMS-T-21014, MIL-T-210014 | Class 1 | Class 1 | |

| ASTM B777 | Class 1 | Class 1 | |

| AMS 7725 | Class 1 Type 2 | Class 1 Type 1 | |

| Nominal Chemical Composition | Ni content % Fe content % Cu content % Co content % W content % | 5.1 | 7.0 2.59 | 3.0 1.95 | = 0.1 | – 90.2 | 90.0 | 6.7 | 8.9 0.2 | 1.1 2.6 | – 0.2 | – 90.2 | 90.0 |

Tungsten Powder Production with ASTM Standards

We use proprietary processes to convert APT or oxide powders into high-purity tungsten metal powders of exceptional quality. We meticulously control every blending step in-house to ensure precise nickel and iron content, meeting ASTM chemistry standards.