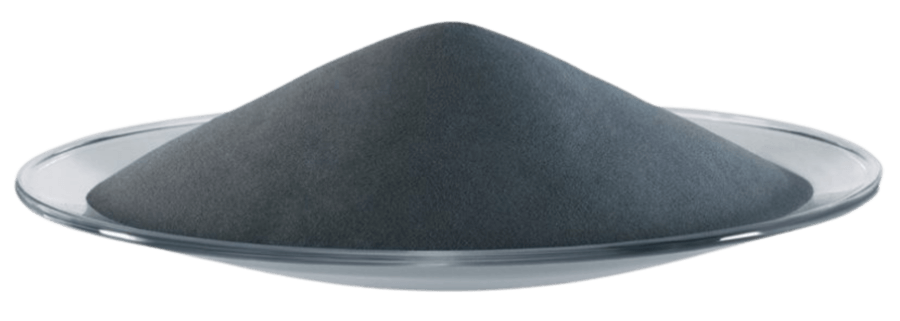

Agglomerated Molybdenum Thermal Spray Powder

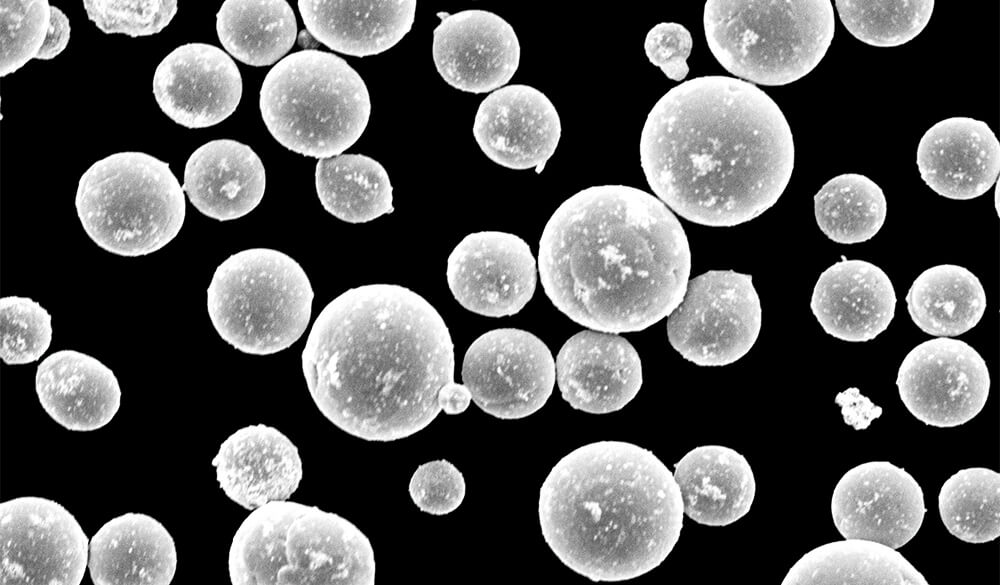

Elmet Technologies is a leading U.S. manufacturer of of high-quality agglomerated molybdenum thermal spray powder, known as SOMP powder. This advanced powder features free-flowing, porous, spherical agglomerates, engineered for superior performance and reliability. Available in both coarse and fine grades, our SOMP powder meets diverse industry needs. We also offer custom sizing to match specific customer requirements. Whether for coating solutions or other demanding applications, Elmet Technologies ensures excellent results, high-quality materials, and dependable performance in its SOMP powder.

Agglomerated molybdenum thermal spray powder enhances and restores surfaces with precision and reliability. It is ideal for a range of applications, from creating durable, large-area protective coatings, to repairing and improving small metal components. Contact our team of experts to discuss your application.

advanced Thermal Spray Powder methods

Elmet Technologies continues to develop its thermal spray powders, extending product lifespan by repairing worn or damaged surfaces and protecting against erosion, wear, and corrosion. These powders are applied with precision, forming a uniform coating of continuous layers on the substrate for enhanced durability and performance.

Additionally, we offer a variety of powders for diverse spraying processes, including plasma, flame, detonation, high velocity air fuel (HVAF), and high velocity oxy-fuel coating spraying (HVOF). These processes leverage our unique powder metallurgy techniques to deposit protective layers on parts, components, or specialized surfaces.

Benefits of AgGlomerated Molybdenum Thermal Spray Powder

Agglomerated molybdenum thermal spray powder, known as SOMP, continues to provide benefits to our customers. Our thermal spray powders are utilized in the application process that deposits powders onto a substrate, resulting in a uniform coating comprised of continuous layers. These benefits to our material includes consistent material behavior, maximizing coverage, and stronger adhesion. Other benefits include:

- Improved deposit efficiency

- Enhanced surface protection

- Smooth, uninterrupted spraying

- Reliable coating performance

Chemical CHaracteristics

- Mass fraction in % [cg/g]; ppm [μg/g]

- Mo – 99.5% min

Physical Characteristics

- Bulk Density – 2 g/cc min

- Hall Flow – 35 s/50 g max

Sieve Analysis

| Coarse | Fine |

|---|---|

| +170 mesh | max. 1% | +325 mesh | max. 1% |

| +200 mesh | max. 15% | -325 mesh | max. 99% |

| -325 mesh | max. 80% |

Custom sieve analysis available per customer requirements.

Size Specifications of Thermal Spray Powders

- Coarse Grade -170+325 mesh

- PWA 1313 -200+325

- Fine Grade -325 mesh

- Finest – PWA 1338

We have the ability to alloy with carbon to produce any level of C content up to 6% (pure Mo₂C). Additional customized alloy powder products are available upon request.

Applications for Thermal Spray Powder

Our thermal spray powders are utilized in a wide range of applications that require exceptional wear resistance, thermal stability, and reliable coating integrity. This includes:

- Transportation

- Chemical plants

- Food manufacturing and packaging

- Mining

- Earth moving equipment

- Power generation

- Plastic extrusion screw flights

- Welding electrodes

high-performance Spraying Processes

At Elmet, we focus on innovation and precision to deliver high-performance powder products tailored for thermal spray applications. Designed to meet the strictest quality standards, our products offer unmatched durability and reliability, even in the most challenging environments. Driven by a commitment to excellence, we partner with our customers to meet their unique needs and help them achieve better results in their applications.

- Plasma

- Flame

- Detonation

- High velocity air fuel (HVAF)

- High velocity oxy-fuel coating spraying (HVOF)