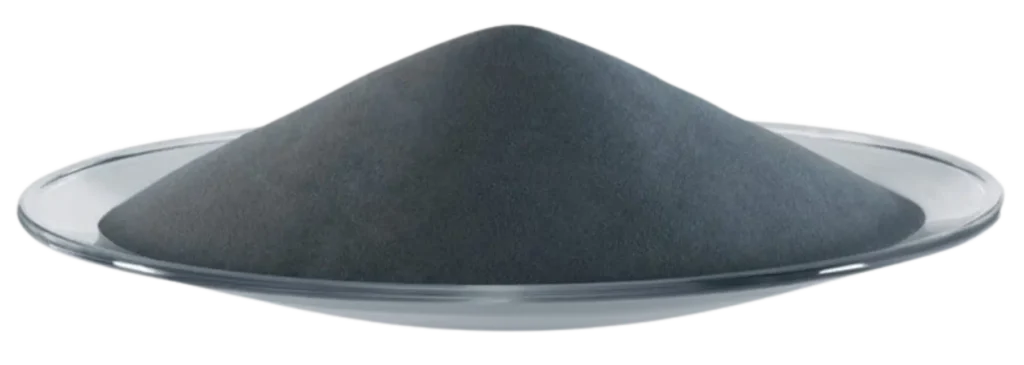

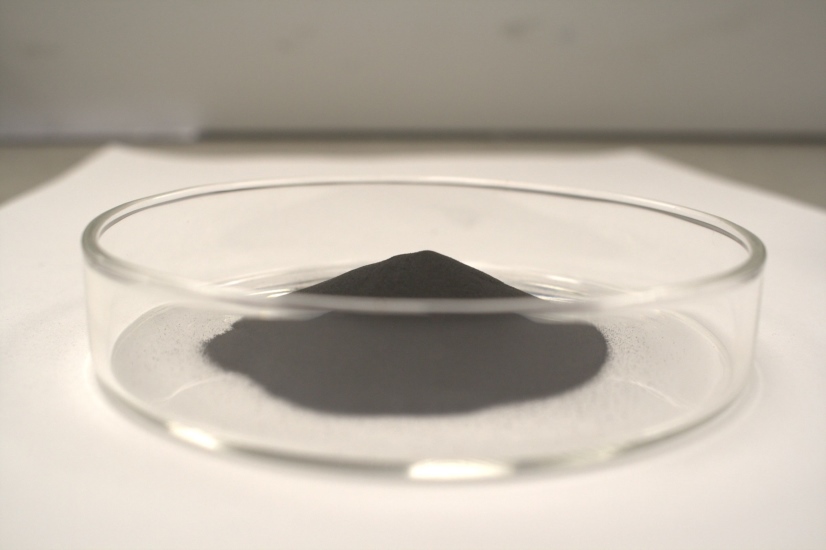

Molybdenum Blended Spherical Powder for Thermal Spraying

Elmet Technologies utilizes its expertise in powder metallurgy to produce advanced molybdenum blended spherical powder for thermal spraying. We offer a wide range of custom-blended powders that extend the lifespan and performance of various mechanical parts, by repairing worn and damaged surfaces, and protecting against the detrimental effects of corrosion, wear, and erosion. Our powder metallurgy techniques are enabling the next-generation of high-performance powders.

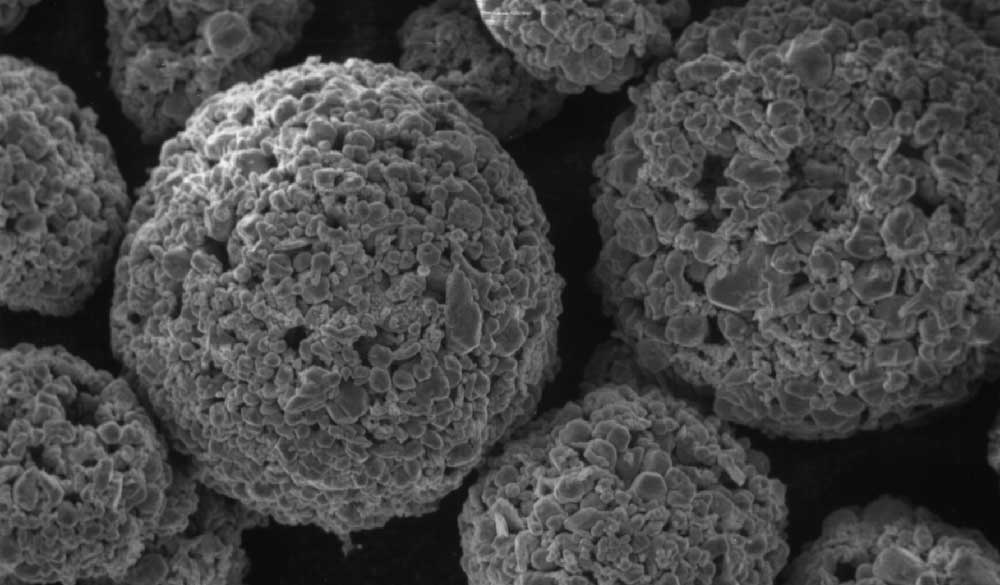

We are renowned for our blended spherical powders, which have superior sphericity and outstanding fluidity. Designed with exceptional purity and high loose packing density, they deliver unmatched quality. Each particle is produced with full internal density, ensuring no hollow imperfections. At Elmet, we lead the industry with innovative refractory metal solutions, delivering top-tier powder metallurgy products tailored to meet your unique material requirements.

High-Quality Molybdenum Blended Spherical Powder

Elmet Technologies expertly blends spray-dried and sintered (SOMP) powders with self-fluxing Ni alloys, meeting AMS 4775 chemistry standards. We also offer NiCr (80/20) and Cr3C2 blend options. We carefully prepare each one using a computer-controlled, loss-in-weight blending system, guaranteeing purity and meeting specific customer needs.

Our expertise in both powder metallurgy and refractory metal manufacturing allows us to create tailored powder and part solutions for your specific needs. At Elmet, we specialize in enhancing thermal spray applications through our highly-engineered powder products.

Start a discussion with our team of experts today to discuss your material requirements.

Specifications and Applications

At Elmet, we offer advanced molybdenum thermal spray powder blends developed to meet both customer and industry specifications. These blended spherical molybdenum powders are engineered with self-fluxing components to create hard, dense coatings that deliver exceptional abrasion and wear resistance. Their spherical morphology ensures superior performance and reliability, making them an ideal choice for demanding applications.

Our agglomerated spherical molybdenum powder, created through a process of sintering and granulation of fine molybdenum powder, contains a narrow particle size distribution, impressive fluidity, and exceptional deposition efficiency.

The following characteristics make BSP ideal for various specialized applications:

- Atmospheric or water-stabilized plasma spraying to create durable molybdenum coatings.

- Spraying and priming purposes.

- Blending with NiCrBSi alloy powder effectively sprays piston rings.

- Standing up against corrosive elements like molten steel and copper in oxygen-resistant environments.

Properties of Blended SPherical Powder

CHEMICAL PROPERTIES

(Mass fraction in % [cg/g]; ppm [μg/g])

Mo (excluding gases) – 99.5% max

PHYSICAL CHARACTERISTICS

| Apparent Density | Hall Flow |

|---|---|

| 30 g/cubic inch min | 35 s/50 g max. |

Blended Spherical Powder sPECIFICATIONS

Pure molybdenum powder for various size specifications:

| Course Grade | -170+325 mesh |

| PWA 1313 | -200+325 |

| Finest | PWA 1338 |

| Fine Grade | -325 mesh |

Experts in Blended Spherical Powders

Elmet is a leader in producing high-quality molybdenum blended spherical powder products. Our powders are meticulously engineered to be spherical and flowable. We enhance the restoration and improvement of surfaces, ranging from extensive area coatings to intricate metal components.

We offer a comprehensive powder metallurgy product portfolio. Our commitment to excellence in materials development and thermomechanical processing ensures the creation of high-performance powders tailored to meet specific customer requirements for the most demanding applications.