Molybdenum Metal Injection Molding Powder Type II

Elmet Technologies manufactures Molybdenum Metal Injection Molding Powder Type II, known as MIMP Type II, with ultrafine agglomerate size. As a leading global provider of high-performance powders, our world-class manufacturing technology and analytical laboratory services enable us to tightly control the processing parameters for a wide range of powder metallurgy products. Our advanced capabilities enable us to match unique size and purity requirements.

For those seeking the finest quality in metal powders, MIMP Type II Powder features highly deagglomerated molybdenum powder. Engineered with high quality materials, it offers high performance in applications requiring the finest powders for ceramic metallization or metal injection molding applications.

Molybdenum Metal Injection Molding Powder Type II Processing

Molybdenum Metal Injection Molding Powder Type II is derived from molybdenum trioxide (MoO3). The MoO3 undergoes heat treatment in a furnace to produce MoMP Powder. This MoMP Powder is then de-agglomerated using a jet mill, ensuring the final MIMP Type II product achieves optimal quality and consistency.

Our engineering team is available to help you select the most suitable powder formulation to meet your specific requirements. By partnering with each customer, we ensure delivery of the the highest quality materials available, tailored to exact project specifications.

Chemical and Physical Properties of MIMP Type II

Chemical Properties

| Mo (excluding gases) | 99.98 % min |

| O | 0.300% max |

| Cr | 0.010% max |

| Fe | 0.020% max |

| Mg | 0.002% max |

| Ni | 0.020% max |

| Si | 0.025% max |

| Sn | 0.008% max |

Physical Characteristics

| Fisher Number (as needed) | Particle Size Distribution | Apparent Density |

|---|---|---|

| 1.5-3.0 μm | D 50% – 2-5 μm D 99% – <14 μm | 1.5-2.5 g/cm3 |

Key Features of Metal Injection Molding Powder Type II

- High purity

- Low oxygen

- Finest agglomerate size

- Lower purity vs. MIMP Type I

- Smaller particle size vs. MIMP Type I

- Precision molding

- Thermal stability

- Reduced material waste

Key Applications for Molybdenum Metal Injection Molding Powder Type II

Ceramic Metallization

MIMP Type II is critical in ceramic metallization, enhancing ceramic surfaces by depositing a metal layer to create a wettable surface for brazing. Metallized ceramics outperform glass equivalents with superior refractory behavior and the ability to form seals with metals. This technology is used in electrical feed-through seals for applications such as vacuum interrupter envelopes and pyrotechnic actuators. Additionally, it excels in high-temperature environments like solid oxide fuel cells, where glass-to-metal seals are insufficient.

Metal Injection Molding

Metal injection molding (MIM) relies on MIMP Type II powder to shape both heavy and light metals with complex geometries to exacting standards. This process enables the efficient production of high-volume, intricate parts in a single step while maintaining the highest quality and performance. After molding, parts undergo critical conditioning operations, such as debinding to remove binders and densification to compact the powders. The resulting components are widely used across industries that demand precision and reliability.

Industrial applications of MIMP Type II

AEROSPACE

The aerospace industry benefits from MIMP Type II Powder by improving component performance under extreme conditions. It helps parts withstand high temperatures, pressure, and corrosion, ensuring reliable and efficient operation.

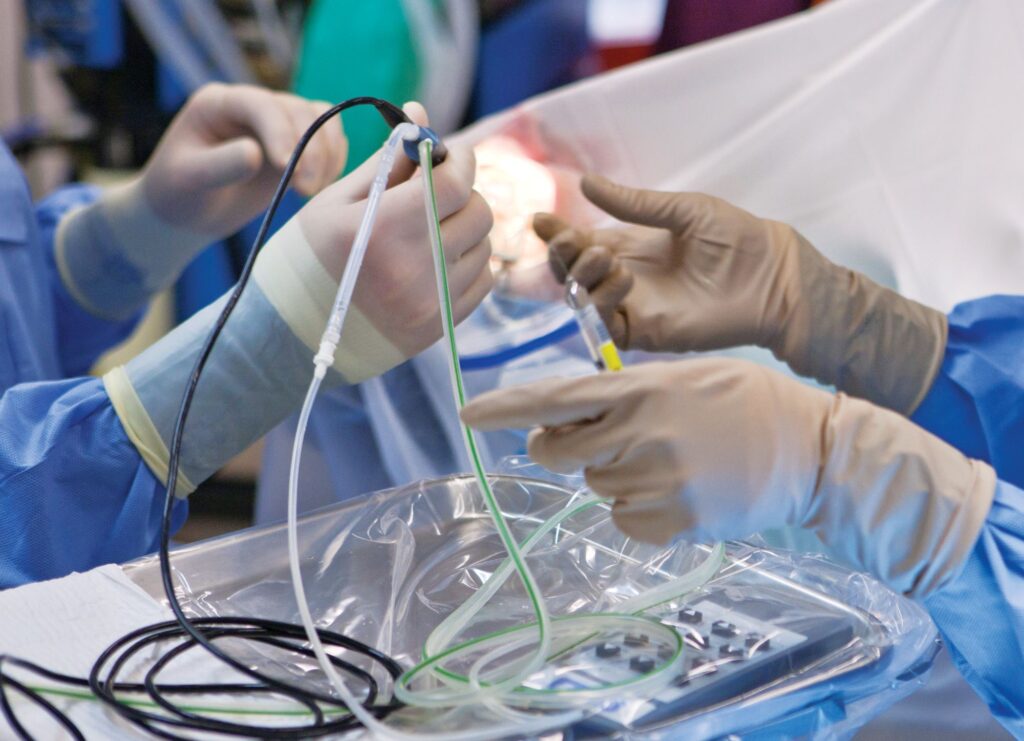

MEDICAL

MIMP Type II in metalized ceramics provides reliability and accuracy, especially in high vacuum and high-pressure situations. It is vital in the medical industry, used in diagnostic imaging and advanced surgical instruments.

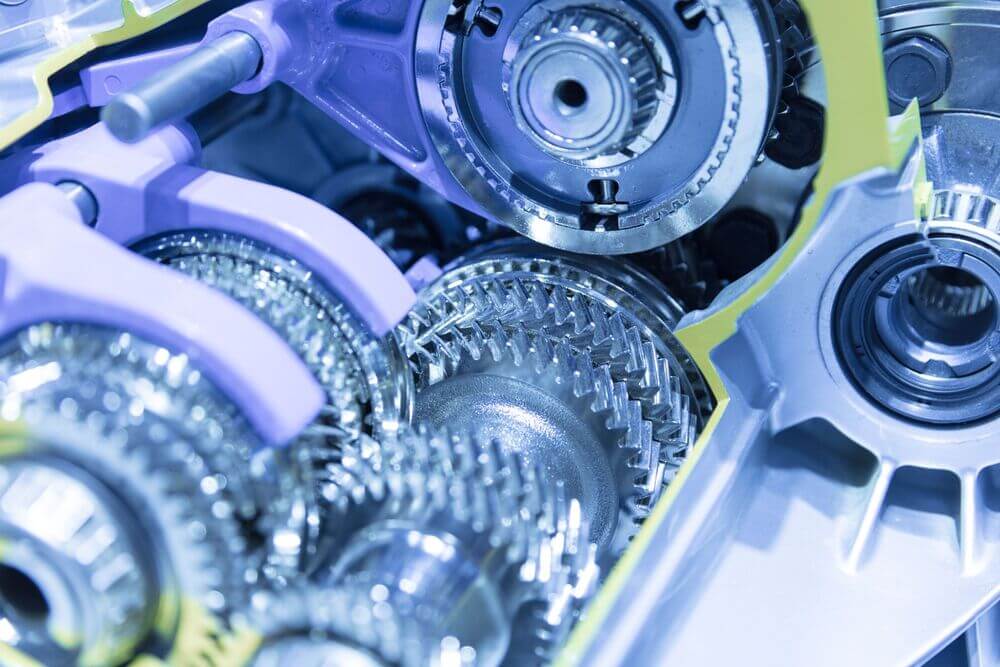

AUTOMOTIVE

MIMP Type II Powder is used in the automotive industry to make intricate parts like gears, connecting rods, and other components. It enables manufacturers to create complex shapes with precise tolerances.

High Performance Refractory Metal Solutions

Elmet Technologies offers a comprehensive portfolio of high-performance powder metallurgy solutions and metal powder products. As a fully-integrated manufacturer, we utilize our own powders to develop complex fabrications, assemblies, finished, semi-finished, and machined products. We also offer toll manufacturing services such as hot and cold rolling, rotary forging, and extrusion.