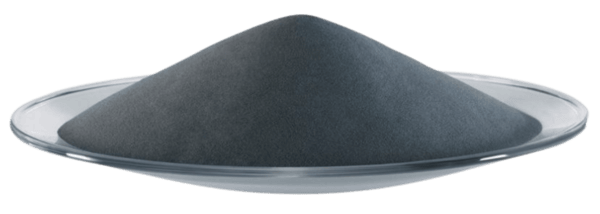

Potassium-Doped Molybdenum Powder

Elmet Technologies is a leading global provider of potassium-doped molybdenum powder for applications requiring high creep resistance. Also known as Mo-K or Moly HCT, this material retains low-temperature ductility even after high-temperature exposure, ensuring reliable performance in extreme conditions.

This advanced material is well-suited for use in resistance heating elements, lamp filament supports, sintering trays, and electronic tube components. Through a precise manufacturing process, recrystallized Molybdenum HCT develops interlocked, elongated grain structures that enhance its durability while maintaining ductility at room temperature and below. Potassium-doped molybdenum powder offers key features including superior structural integrity and robust thermal resilience, making it an ideal choice for demanding industrial applications that require exceptional material reliability.

Pure Molybdenum vs. HCT Molybdenum

Unlike pure molybdenum, which becomes brittle after prolonged exposure to elevated temperatures, Potassium-doped molybdenum powder forms interlocked, elongated grain structures during recrystallization. This results in superior performance in high-temperature applications. The unique microstructure ensures greater ductility at room temperature and below, reducing the risk of unexpected failures caused by vibration or mechanical handling.

Achieved through precise alloying and thermomechanical processing, HCT maintains less than 200ppm residual alloy content while preserving essential properties such as density, heat capacity, thermal expansion, and modulus. Additionally, the cold electrical resistivity of Potassium-doped molybdenum is approximately 5% higher than pure molybdenum, making it an excellent choice for applications requiring reliability and durability.

Potassium-Doped Molybdenum Products: Rod

Elmet Technologies utilizes its potassium-doped molybdenum powder to manufacture rods in the following sizes:

Standard Diameter Tolerances (inches)

| Diameter | Black/Clean | Ground |

|---|---|---|

| .020-.025 | ±.001 | ±.001 |

| .025-.070 | ±.0015 | ±.001 |

| .070-.200 | ±.002 | ±.001 |

| .200-.250 | ±.007 | ±.001 |

| .250-.435 | ±.007 | ±..0015 |

| .425-.750 | ±.010 | ±.003 |

| .750-1.000 | ±.015 | ±.005 |

| 1.000-1.250 | ±.015 | ±.005 |

| 1.250-1.750 | ±.025 | ±.005 |

| Diameter | .5″-12″ | 12″-24″ | >24″ |

|---|---|---|---|

| .020-.100 | ±.010 | ±.015 | ±.0625 |

| .100-.500 | ±.015 | ±.015 | ±.0625 |

| .500-1.000 | ±.015 | ±.030 | ±.0625 |

| 1.000-1.500 | ±.030 | ±.0625 | ±.0625 |

Elmet Technologies is able to accommodate tighter tolerances upon request.

Potassium-Doped Molybdenum Products: Sheet

Elmet Technologies utilizes its potassium-doped molybdenum powder to manufacture sheet in the following sizes:

| Thickness | Max Width |

|---|---|

| .005″ to .015″ | 24″ |

| > .015″ to .040″ | 24″ |

| > .040″ to .090″ | 24″ |

Material from .005 inches to .090 inches in thickness is classified as molybdenum HCT sheet. Other sizes and tolerances are available, including wider plate and sheet products from our rolling mill.

Surface condition required and width determine length.

Our Advanced Metallurgy Process

Elmet Technologies specializes in producing high-quality potassium-doped molybdenum powder through an advanced, fully integrated manufacturing process. Starting with raw materials, we purify them into molybdenum metal powder using a precise chemical reduction method. Through the controlled steps of mixing, pressing, deformation, and heating, we refine the powder to achieve specific characteristics essential for performance, such as enhanced strength, reduced porosity, and improved temperature resistance.

Our expertise in powder metallurgy techniques ensures consistent and reliable potassium-doped molybdenum powder tailored for demanding applications.