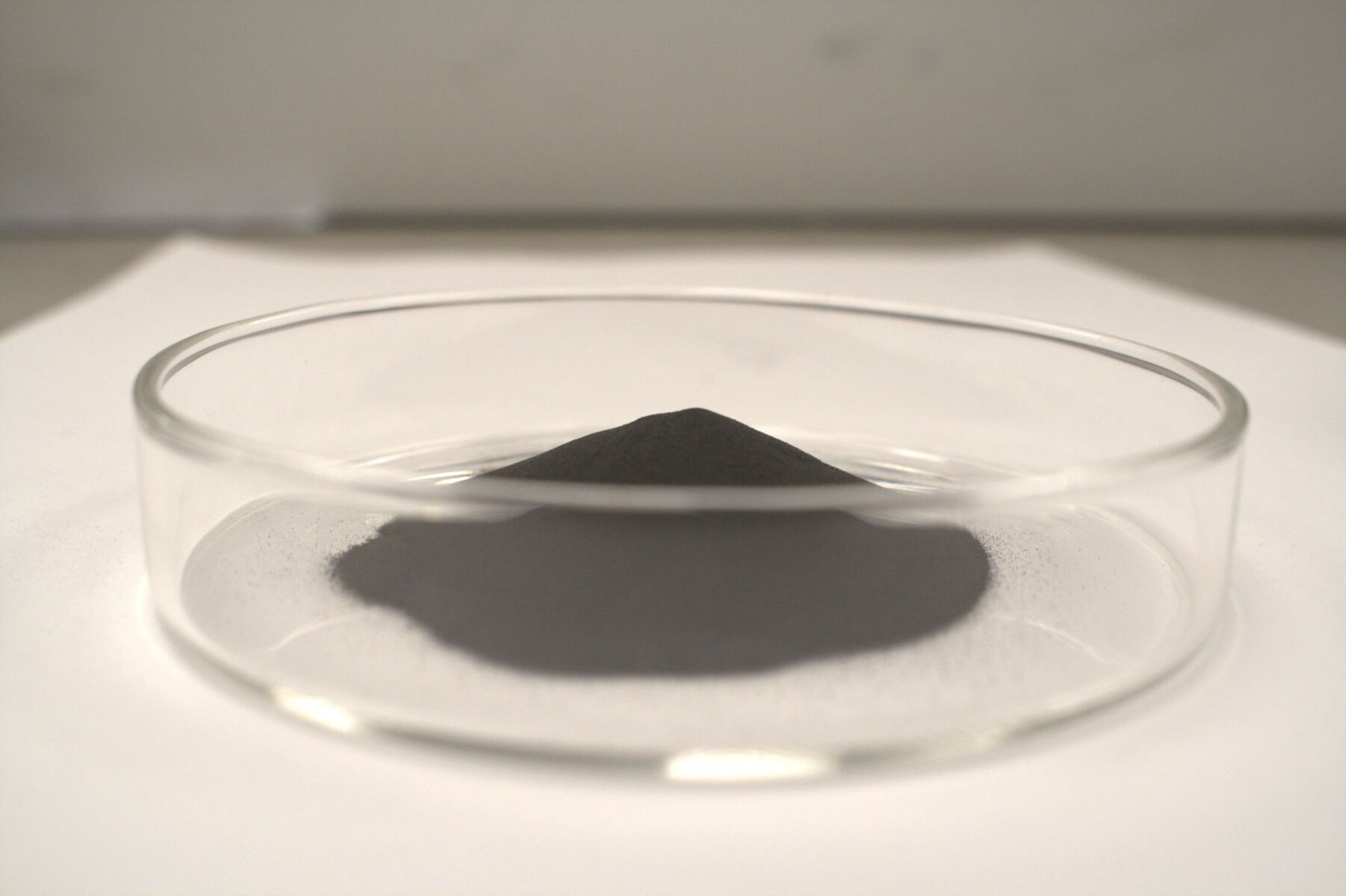

Molybdenum Alloy Powders

Elmet Technologies is a leader in developing, engineering, and manufacturing molybdenum alloy powders for high-performance applications. Our expertise in refractory metal manufacturing allows us to continue developing innovative powder metallurgy solutions for our customers. We specialize in custom-formulating powders to meet your exact specifications. With precise control over agglomerated grain structures, green strengths, and particle sizes, we ensure our powders are perfectly suited for a wide range of specialized applications. These capabilities are the driving force behind our next-generation of powder metallurgy techniques.

Molybdenum alloy powders are highly versatile, with an ability to be processed via a range of techniques. This includes: additive manufacturing, powder metallurgy, arc melting, electron beam melting, extrusion, forging, and hot and cold rolling. Powder metallurgy (PM) encompasses a range of modern engineering techniques, ranging from isostatic pressing to plasma spray coating. Elmet Technologies powders can also be finely tuned to suit customer specifications.

Thermal Benefits of Molybdenum Alloy Powders

Molybdenum alloy powders and consolidated molybdenum products are widely used in thermal management applications because of their characteristics, such as:

- High thermal conductivity

- Low coefficient of thermal expansion

- High melting point and strength at elevated temperatures

Molybdenum Alloys: Semi-Finished Parts

Elmet Technologies provides molybdenum products in a range of semi-finished forms:

- Tubes

- Bar, Billet, Forging

- Discs, Squares, Cubes

- Pellets

- Rod, Wire, Coil

- Sheet, Plate, Foil

Physical Properties of Molybdenum-Based Powders

| Typical Ranges | Particle Size Distribution | ||||

|---|---|---|---|---|---|

| Standard Screen Mesh | μm | FSSS# (μm) | Bulk | Tap (g/cc) | D10 | D50 | D90 (μm) | Product Data Sheet | |

| MoMP | -230 | <63 | 3.5-5.5 | 1.0-2.0 | 2.5-4.0 | 10 | 20 | 40 | 8010 |

| OMP | -200 | <75 | 2.5-3.5 | 1.0-2.0 | >2.0 | 7 | 15 | 45 | 800450 |

| MIMP-Type I | -500* | <25 | 3.5-5.5 | 2.0-3.5 | >3.0 | 2.5 | 5.5 | 13 | 8009 |

| MIMP-Type II | -635* <20 | 1.8-2.5 | 1.5-3.0 | >2.5 | 1.5 | 3.5 | 6 | 8009 |

| Mo2C | Customer Specific | 3.0-5.5 | 1.0-2.0 | >2.0 | 5 | 10 | 3 | – |

| Spec Purity % | Potential Purity % | Typical Measurements (ppm) Oxygen | Cr | Fe | Mg | Ni | Si | Sn | |

|---|---|---|---|

| MoMP | .>99.95 | >99.97 | <600 | 6 | 15 | 4 | 5 | 3 | 1| |

| OMP | >99.80 | >99.90 | <1000 | 10 | 60 | 5 | 10 | 100 | 3 |

| MIMP-Type I | >99.5 | >99.97 | <1500 | 6 | 20 | 4 | 5 | 3 | 1 |

| MIMP-Type II | >99.80 | >99.90 | <2000 | 30 | 70 | 10 | 25 | 120 | 5 |

| Mo2C | >93.00 | 5.5-6.5 C | NA |

Molybdenum Alloys: common Materials

Elmet Technologies is one of the largest providers of high-purity pure Mo and molybdenum alloy powders, semi-finished products, and complex fabrications. Molybdenum can be used in its pure form, and is also commonly combined with other materials to form a range of high-performance alloy materials. This includes: TZM, MHC, MoLa, MoTi, MoW, MoZrO2, MoRe, HCT Mo, CuMoCu, and more.