Molybdenum

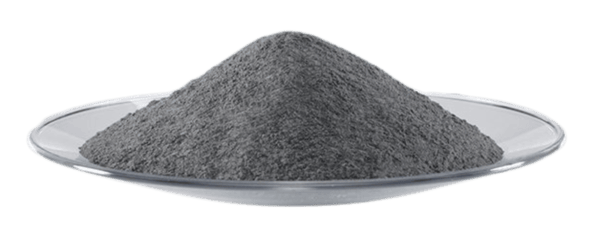

Elmet Technologies is a leading North American producer of pure molybdenum (Mo). We are unique in our ability to perform end-to-end manufacturing, starting with molybdenum oxide reduction to produce high-purity Mo metal powder. We then transform this powder using advanced powder metallurgy techniques – pressing, sintering, rolling, swaging, and drawing – to create fully dense flat and round mill products. Our comprehensive range of products includes rods, sheets, plates, foils, wires, and more, available for direct purchase or further enhancement through our world-class fabrication and machining services.

We precisely control material properties like ductility, tensile strength, hardness, and grain size through our comprehensive manufacturing process, tailoring each product to meet specific application needs. Elmet is committed to excellence, operating under ISO9001 and AS9100 certified quality management systems.

Characteristics of Molybdenum

- Symbol: Mo

- Category: Transition Metal, Group VI

- Atomic Number: 42

- Density: 10.28 g / cm3

- Discovered: 1778

- Molybdenum melting point, 2620°C

- Load bearing capabilities at high temperature

- Excellent thermal and electrical conductivity

- Low vapor pressure at high temperatures

- Low coefficient of thermal expansion

- Resistance to corrosion

- Shielding from high energy particles

High-Performance Metal Solutions

Discover a wide range of molybdenum products designed for exceptional performance. These products are tailored to meet the demands of diverse industrial applications:

High-Temperature Strength

- Melting point of 2620°C; ideal for industrial furnaces (1600°C–2000°C).

- Requires protective atmospheres above 400°C (vacuum, inert gas, etc.).

- Excellent thermal and electrical conductivity.

- Low vapor pressure; suitable for metal injection molding and vacuum applications.

- Used in nuclear fuel sintering and glass melting furnaces.

Corrosion

Resistance

- Enhances efficiency and longevity in demanding environments.

- Key for electrodes and flow control in glass melting processes.

- Used in semiconductor ion etching grid sets for precision and strength.

- Essential for MOCVD reactor components and assemblies.

- Hot runner nozzles in plastic injection molding resist heat and abrasion.

Coefficient of Thermal Expansion

- Low expansion rate matches materials like glass and silicon.

- Critical for lighting, flat panel displays, and electronics.

- Bonds with silicon or glass, ensuring thermal cycling stability.

- Provides durability and reliability in high-temperature applications.

- Ensures long-term performance in precision engineering and manufacturing.

Molybdenum ALloys in high temperature ENVIRONMENTS

- MoLa: A composite blend of molybdenum and lanthanum oxide (La2O3), is valued for high-temperature applications. Its outstanding mechanical strength and thermal stability make it an exceptional choice for demanding environments.

- TZM: Offers increased strength at elevated temperatures compared to pure molybdenum. Additionally, TZM features a higher recrystallization temperature and enhanced resistance to creep.

- HCT: Ideal for applications requiring low-temperature ductility after high-temperature exposure. Perfect for heating elements, lamp supports, sintering trays, and electronic components. Recrystallized HCT molybdenum forms elongated grains, maintaining excellent ductility even at low temperatures.