C103 Powder

C103 powder is a Nb-based alloy with high temperature strength, most commonly utilized in aerospace, propulsion, and hypersonic applications. It is also used in energy, chemical, and scientific industries. The complex structure of C103 offers extreme mechanical strength and high stability, even in the most demanding high temperature environments. As the demand for advanced materials and AM technologies grows, the applications for C103 powder continue to expand even further.

C103 alloy typically consists of niobium (Nb), hafnium (Hf), and titanium (Ti). However, Nb-based alloys can often have their compositions custom-tailored to fit unique application requirements. The most notable features of C103 powder include its high tensile strength, high ductility, corrosion resistance, high thermal conductivity, relatively low density, and exceptional mechanical strength. It is gaining fast adoption in 3D printing technology to produce complex components.

C103 Material for High-Performance Products

C103 powder represents a cutting-edge, high-performance solution specifically engineered for advanced manufacturing processes. In the demanding aerospace industry, C103 powder is frequently used for critical applications. These include the fabrication of robust rocket engine components, precision-engineered nozzles, and other vital parts requiring strength, heat resistance, and complex forms. Its unique properties make it an indispensable material for pushing the boundaries of aerospace innovation.

Benefits of C103 Powder

- Excellent high-temperature strength

- Superior oxidation resistance

- Stable mechanical properties

- Outstanding ductility and formability

- Consistent powder metallurgy performance

- Compatibility with new AM technologies

Chemical Characteristics

| Element | Percent % |

|---|---|

| Nb | 88 min |

| Hf | 9-11 |

| Ti | 0.7-1.3 |

| Ta | 0.5 max |

| W | 0.5 max |

| Zr | 0.7 max |

| C | <0.015 |

| O | <0.05 |

Key Properties of C103 Powder

- Low oxygen content to enhance material quality

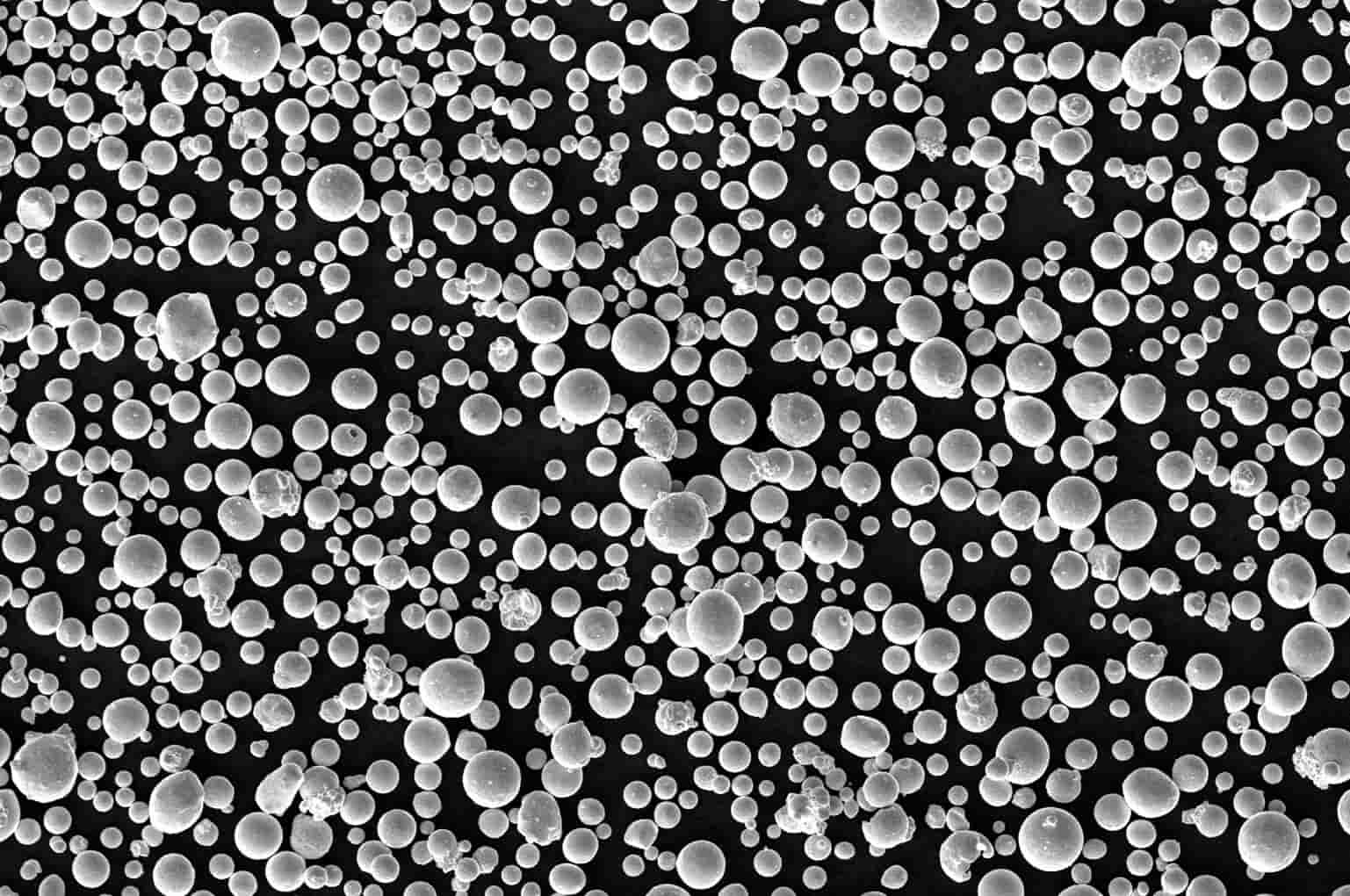

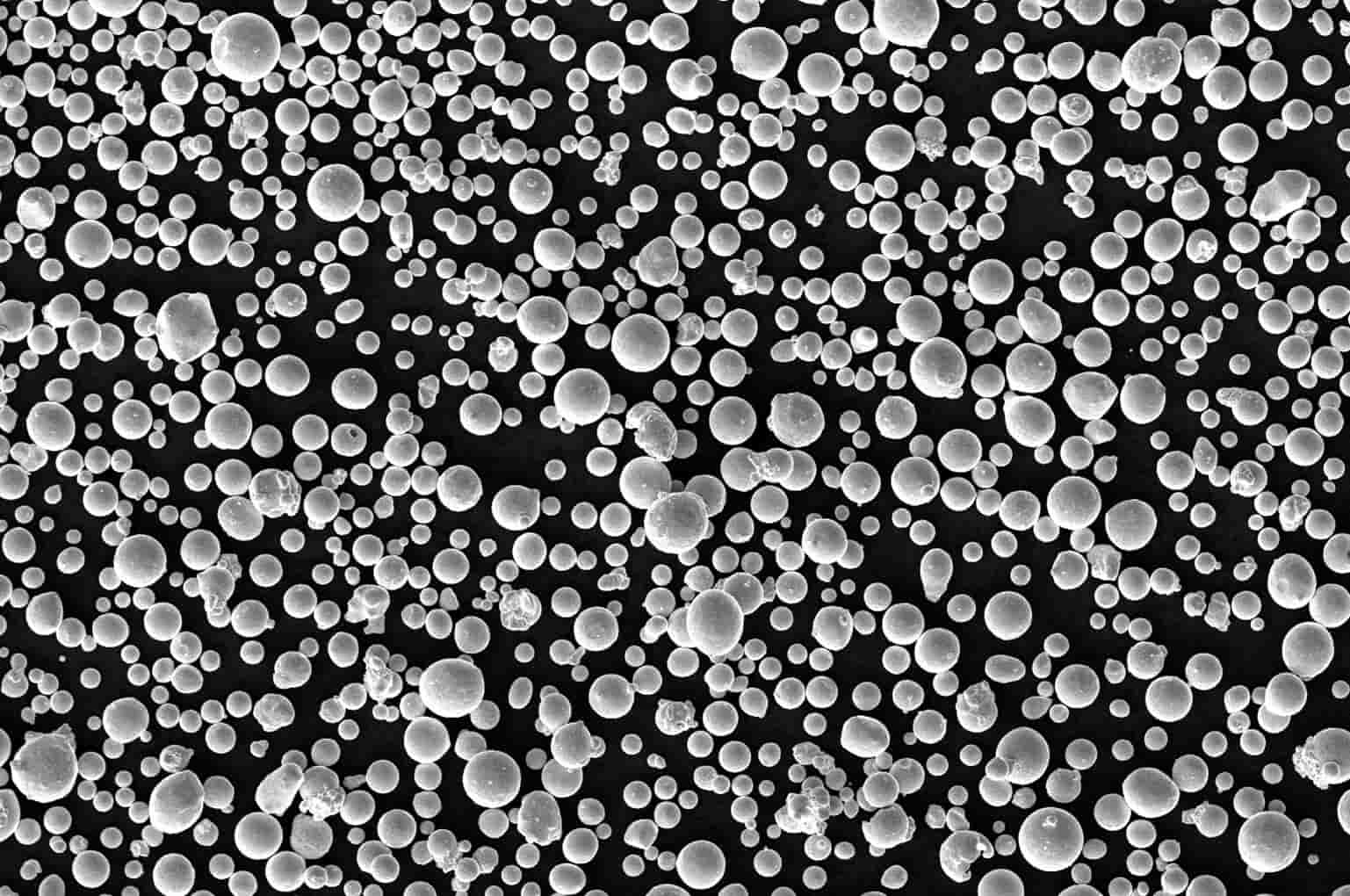

- Spherical particle shape for optimal performance

- Uniform elemental distribution ensuring consistency

- Excellent flowability for seamless processing

Physical Characteristics

| Property | L-PBF | DED |

|---|---|---|

| Bulk Density, g/cc | >4.5 | >4.5 |

| Flow, s/50g | <15 | <17 |

| PSD. d10. μm | >10 | >40 |

| PSD, d90, μm | <53 | <150 |

C103 Powder: Common Applications

AEROSPACE

C103 has become the leading choice for satellite and rocket motor propulsion, playing a critical role in advancing aerospace technology.

AM PRINTING

Elmet Technologies specializes in producing intricate, high-performance components using advanced laser-powder bed fusion technology.

DEFENSE

C103 plays a critical role in fighter jet engine exhaust systems and serves as a key material for the leading-edge components of hypersonic vehicles.

Next-Generation C103 Solutions

Elmet Technologies is leading the way in developing the next-generation of C103 powder metallurgy products and solutions. Our metal processing and product capabilities include extrusion services, 3D printed parts, bar and rod, powders for AM, and more.

Our innovative materials are highly-engineered to meet your most unique requirements. Speak with our team of experts to learn more about our materials, products, and solutions.