TZM Additive Manufacturing Powder

Elmet Technologies is a global leader in providing premium TZM additive manufacturing powder, tailored for 3D printing processes. This advanced alloy powder is composed of 0.50% titanium, 0.08% zirconium, 0.03% carbon, and balanced with molybdenum. It is a high-performance material with outstanding mechanical and thermal properties. It boasts a high melting point, excellent thermal conductivity, and superior strength and toughness compared to pure molybdenum.

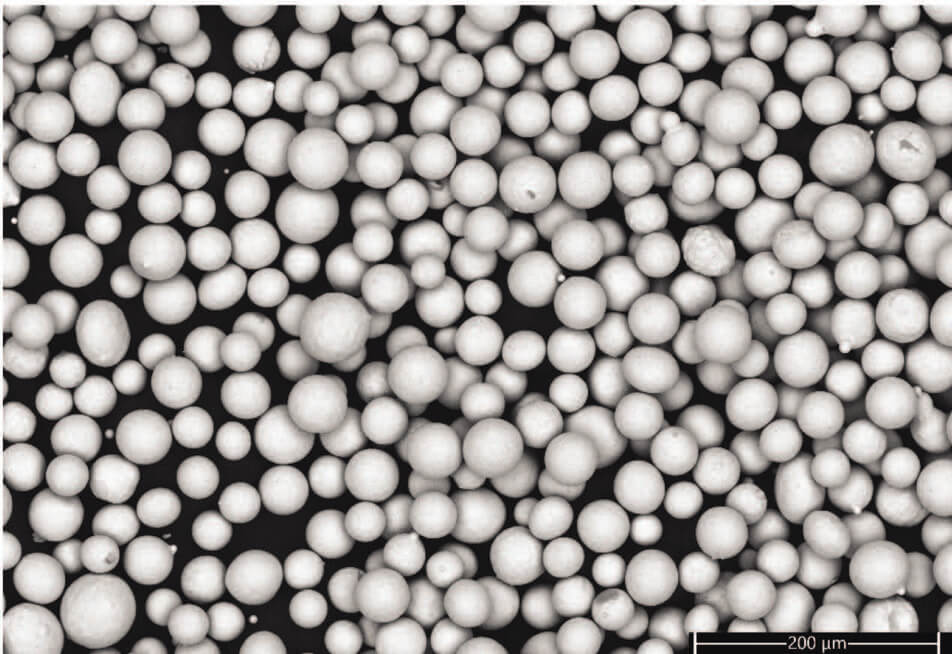

Engineered with low oxygen content, excellent flow characteristics, and high apparent and tap densities, TZM AM powder offers exceptional durability and resistance to corrosion. These qualities make it an ideal choice for demanding applications requiring top-tier performance in high-temperature environments.

TZM AM Powder Chemical Characteristics

| Element | Percent% |

| Mo | 99.2 min |

| Ti | 0.4 – 0.55 |

| Zr | 0.06 – 0.12 |

| C | < 0.15 |

| O | < 0.1 |

TZM AM POwder Physical Characteristics

| Property | DED | L-PBF |

| Bulk density, g/cc | > 5 | > 5 |

| Flow, s/50g | < 17 | < 15 |

| PSD, d10, µm | > 40 | > 10 |

| PSD, d90, µm | < 150 | < 53 |

Key Chracteristics of TZM Additive Powder

- Durability and Strength

- Retains its structural integrity even under high-temperature conditions.

- Resistance to Creep

- Performs exceptionally well in prolonged high-temperature environments.

- High Melting Point

- Ideal for applications requiring superior heat resistance.

- Oxidation Resistance

- Enhanced oxidation resistance compared to pure molybdenum when combined with TZM.

High-Performance TZM Products

- TZM Sheet: Elmet manufactures cold-rolled TZM sheet in customizable thicknesses and lengths to fit your needs. Starting with metal powder, the process involves pressing the powder into ingots, sintering, hot-rolling into plate, and cold-rolling into the final sheet form.

- TZM Rod: Available in diameters from 0.030″ to over 1.0″, our TZM rods can be customized for thickness, length, and surface finish. We offer threaded, precision-machined, and gun-drilled options. Produced from metal powder, the rods are pressed into ingots, sintered, swaged, and drawn to deliver optimal performance.

Molybdenum Powders for AM

| Powder Grades | Chemistry | Size | Other Notes |

| Mo-TZM | 0.5%Ti – 0.1% Zr | L-PBF and DED | – |

| MoRe | Mo10, 41, 48 Re | L-PBF and DED | Available upon request |

| Mo-HfC | 1% Hf | L-PBF and DED | Also made as Mo7ReHfC |

| Mo-La | 1.2% La2O3 | L-PBF and DED | Under development |

Advanced Refractory Metals for Additive Manufacturing

We engineer our refractory metal materials to meet the specific needs of additive manufacturing. We design them with ultra-high purity and tailored properties to improve printability and performance. Using cutting-edge production techniques, we deliver exceptional quality and precision, making them ideal for challenging applications in a wide range of industries.