Tungsten Rhenium Additive Manufacturing Powder

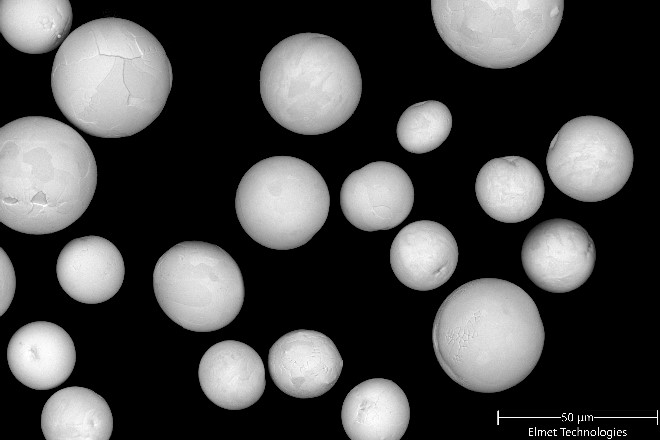

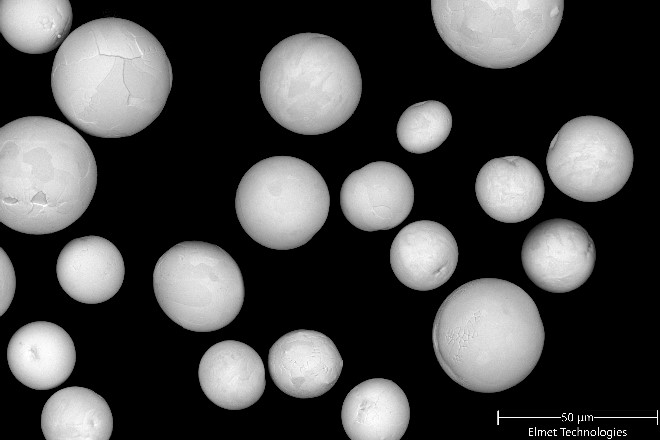

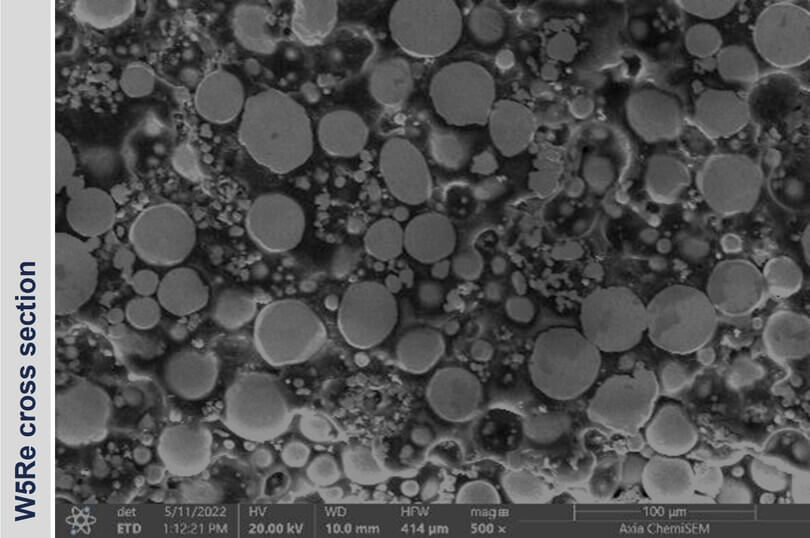

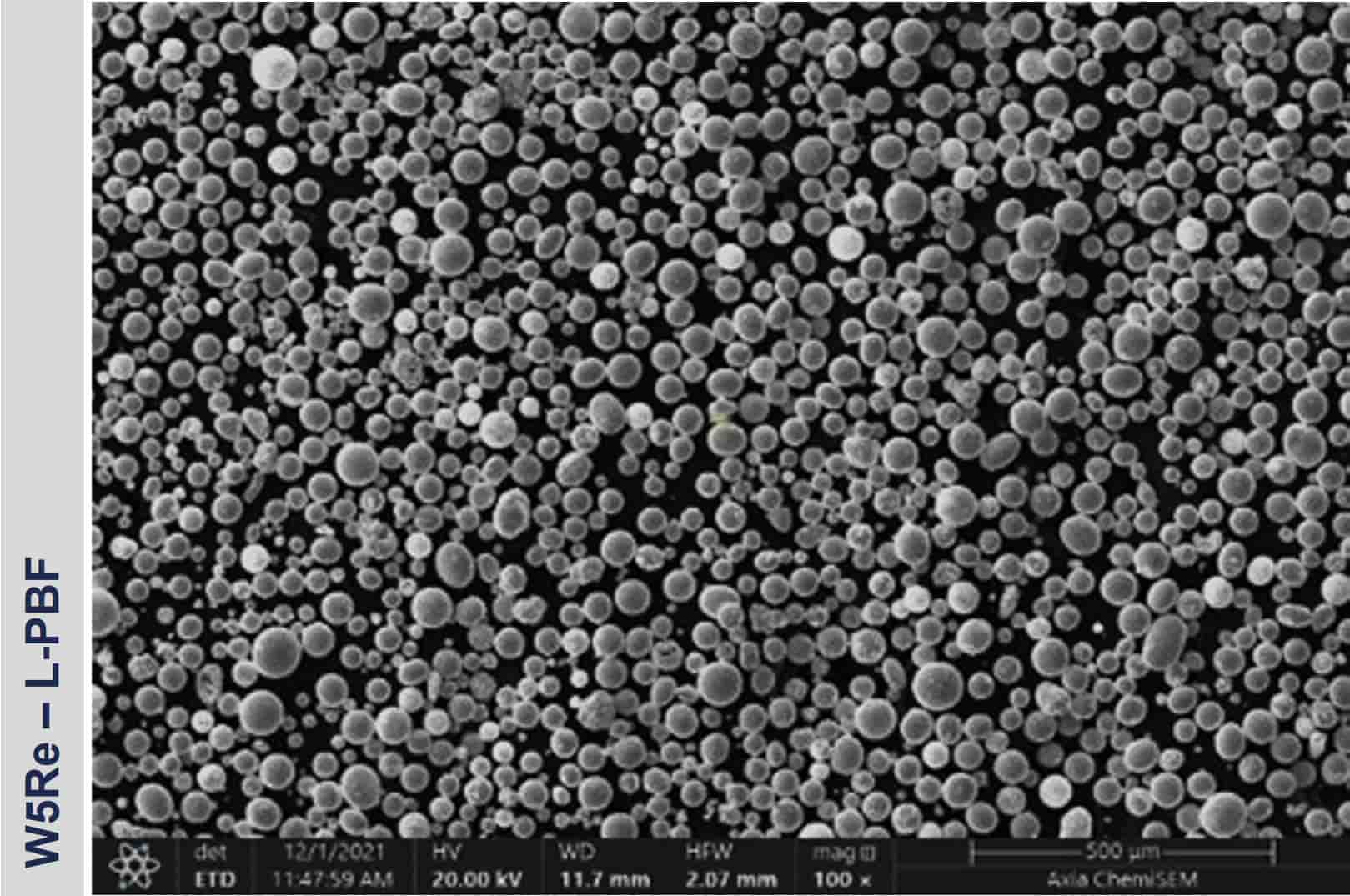

Elmet Technologies produces tungsten rhenium additive manufacturing powder (W + 1-24% Re) tailored for 3D printing processes. The addition of rhenium enhances mechanical performance, delivering outstanding high-temperature strength and creep resistance. This powder stands out for its low oxygen levels, excellent flow characteristics, and high apparent and tap densities.

Tungsten rhenium AM powder is vital in numerous industries due to its durability and ability to perform under extreme temperatures. It is used in aerospace components, high-power electronics, medical devices, and experimental research, making it a key material for advanced applications.

Tungsten Rhenium Additive Manufacturing Powder:

Technical Specifications

Chemical Characteristics

| Element | Percent% |

| W2 | 99 – 76 |

| Re2 | 1 -24 |

| C | < 0.01 |

| O | < 0.03 |

Physical Characteristics

| Property | DED | L-PBF |

| Flow, s/50g | < 9 | < 8 |

| Bulk density, g/cc | > 10 | > 10 |

| PSD, d10, µm | > 40 | > 10 |

| PSD, d90, µm | < 150 | < 53 |

tungsten rhenium AM powder Properties

W-Re powder combines tungsten and rhenium for exceptional durability in high-temperature, harsh environments.

Key properties of tungsten rhenium additive manufacturing powder include:

- High Melting Point

- Strength and Ductility

- Thermal Stability

- Corrosion and Oxidation Resistance

- Electrical Conductivity

Tungsten Rhenium Powders for AM

| WRe Powder Grades | Hall Flow Rate (s/50g) | Bulk Density (g/cc) | Particle Size D10 (mm) | Particle Size D50 (mm) | Particle Size D90 (mm) |

| W1Re (L-PBF / DED) | 5 / 6 | 10.2 / 9.9 | 14 /42 | 25 / 57 | 45 / 88 |

| W3Re (DED) | 8 | 8.7 | 45 | 62 | 95 |

| W5Re (L-PBF / DED) | 6 / 6 | 9.7 / 10.3 | 20 / 47 | 35 / 63 | 49 / 93 |

| W7Re (L-PBF) | 5 | 10.2 | 16 | 26 | 43 |

| W24Re (L-PBF) | 5 | 10.7 | 15 | 25 | 39 |

Advanced Refractory Metal Powder Solutions

Elmet Technologies is your trusted partner for advanced refractory metal powder solutions. With expertise in powder blending, spray drying, plasma densification, powder metallurgy, and alloy development, we deliver unmatched capabilities to meet your needs. Driven by a commitment to innovation, our focused R&D efforts ensure we stay at the forefront of advancements in refractory metal powders.