Tantalum Additive Manufacturing Powder

Elmet Technologies brings decades of powder metallurgy expertise to the development and production of tantalum additive manufacturing powder. As the only fully-integrated and U.S.-owned-and-operated manufacturer of high-purity refractory metal products, we proudly offer advanced, gas-atomized spherical tantalum powders, designed specifically for additive manufacturing (AM) processes with defense, aerospace, medical, energy, and scientific end-markets.

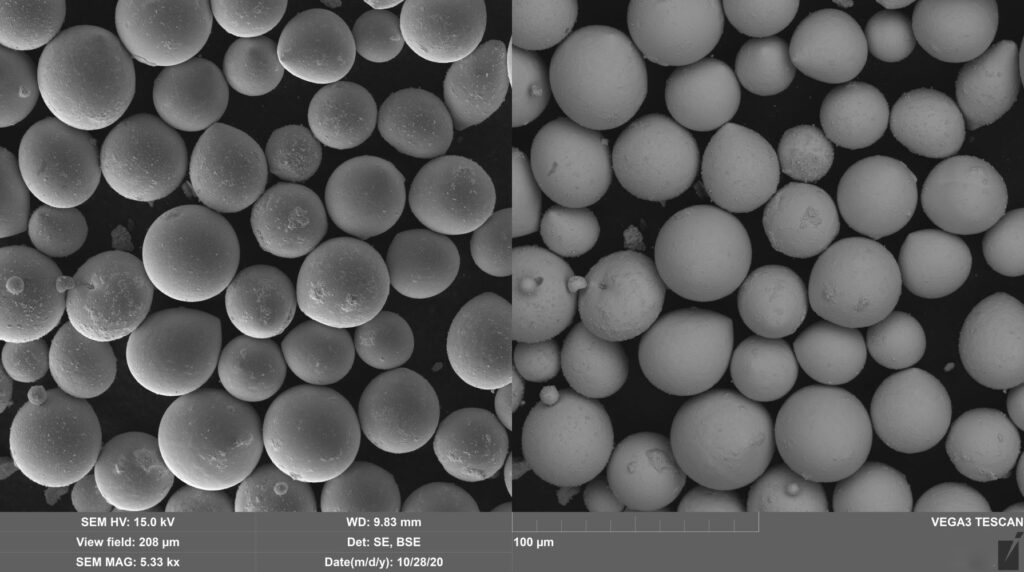

Our powders are optimized for exceptional performance, featuring excellent flowability, high tap density, and a precise particle size distribution. They are perfectly suited for metal AM processes like Laser Beam Powder Bed Fusion (L-PBF), Electron Beam Powder Bed Fusion (E-PBF), and Directed Energy Deposition (DED). Tantalum offers unique qualities, including: high-temperature strength, corrosion resistance, biocompatibility, and radiopacity. This makes it an essential material in aerospace, medical, and several industrial applications. Elmet Technologies focuses on cutting-edge AM powders that meet the most demanding requirements.

Chemical Characteristics

| Element | Percent% |

| Tantalum | 99.9 min |

| Carbon | 100 max. ppm wt |

| Oxygen | 400 max. ppm wt |

Physical Characteristics

| Property | Unit | 15 – 63 μm | 63 – 105 μm |

| Flow rate / 50g 0.1 inch 0.2 inch | s | < 12 < 3 | < 12 < 3 |

| Tap Density | g/cm³ | > 9 | > 9 |

| D10 | μm | 15 – 30 | 50 – 65 |

| D50 | μm | 30 – 45 | 65 – 85 |

| D90 | μm | 45 – 65 | 85 – 110 |

Advanced Tantalum Additive Manufacturing Powder

Our tantalum AM powder represents decades of manufacturing excellence and unwavering dedication to quality. This advanced powder delivers consistent results you can trust. Key features include:

- Ultra-high purity levels exceeding 99.95% for exceptional performance

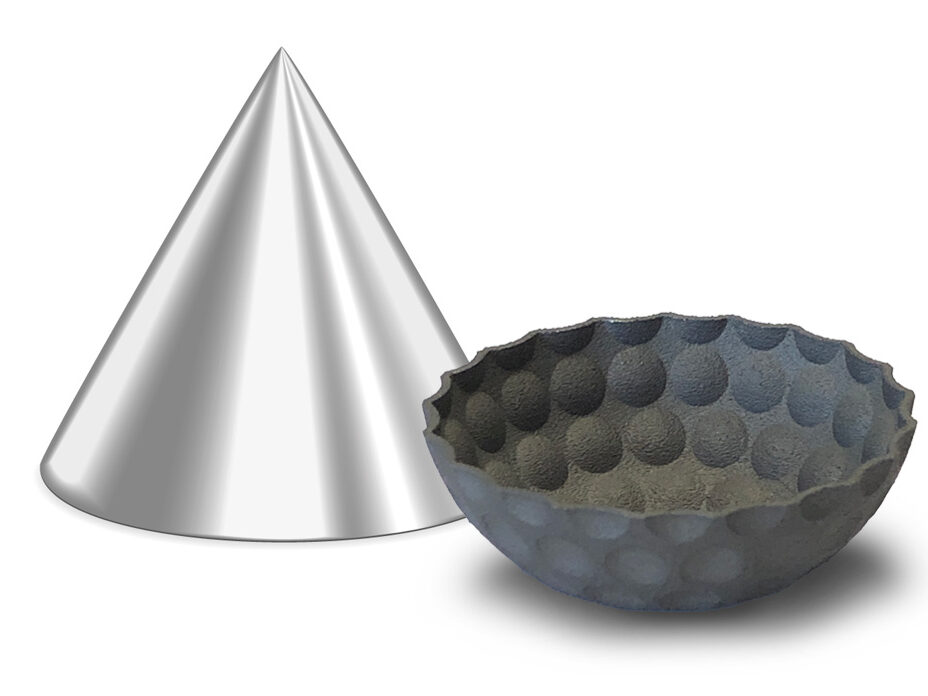

- Optimized spherical particles for superior flow and layer formation

- Complete traceability from raw materials to finished product

- Precisely controlled particle size compatible with L-PBF and DED technologies

With our tantalum AM powder, you can achieve reliable, high-performance results for your advanced manufacturing needs.

Key Applications Across Critical Industries

Tantalum AM powder is driving innovation across critical industries:

- Medical & Biomedical

- Orthopedic implants, surgical devices

- Aerospace & Defense

- Radiation shielding, defense hardware

- Rocket nozzles, turbines, propulsion parts

- Industrial Processing

- High-temperature furnace and chemical equipment

- Corrosion-resistant exchangers, reactor vessels

advanced tantalum powder for extreme environments

Tantalum’s exceptional characteristics make it essential for high-performance manufacturing and critical applications. Our advanced tantalum AM powder is designed to provide:

- High-Temperature Stability: Retains structural integrity in extreme conditions, performing reliably at temperatures over 3,000°C, ideal for high-heat industrial applications.

- Exceptional Corrosion Resistance: Withstands harsh chemical conditions, reducing downtime, maintenance costs, and extending equipment lifespan.

- Long-Term Durability: Designed for minimal wear and degradation, ensuring consistent performance over time.

- Biocompatibility: A trusted choice for medical implants, offering excellent integration and superior imaging visibility.

Tantalum Powder for Additive manufacturing

| Powder Grades | Chemistry | Size | Other Notes |

| Tantalum Tungsten | 2.5 – 10% W | L-PBF and DED | DED size potentially available |

| Tantalum | > 99.9% | L-PBF and DED | < 500ppm O2 |

Your trusted leader in am Solutions

Elmet Technologies is a leader in additive manufacturing, offering high-quality AM powders and 3D printed parts with exceptional performance and reliability. With fully integrated manufacturing facilities, backed a team of experienced metallurgists and engineers, we ensure fast delivery times, minimized supply chain risks, and expert support from our entire team. Every batch of powder is rigorously tested for consistency, making Elmet a trusted partner in powder metallurgy solutions.