Molybdenum Rhenium Additive manufacturing Powder

Elmet Technologies offers molybdenum rhenium additive manufacturing powder (Mo + 10-48% Re), optimized for 3D printing. Engineered to meet the demanding standards of industries such as aerospace, defense, medical, energy, and industrial manufacturing, this advanced material delivers exceptional performance in the most challenging applications.

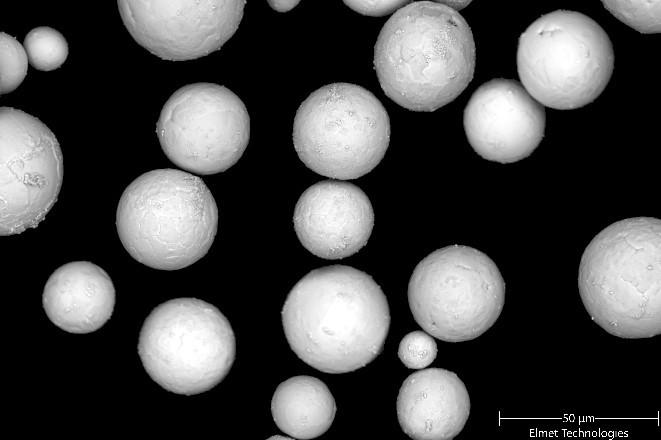

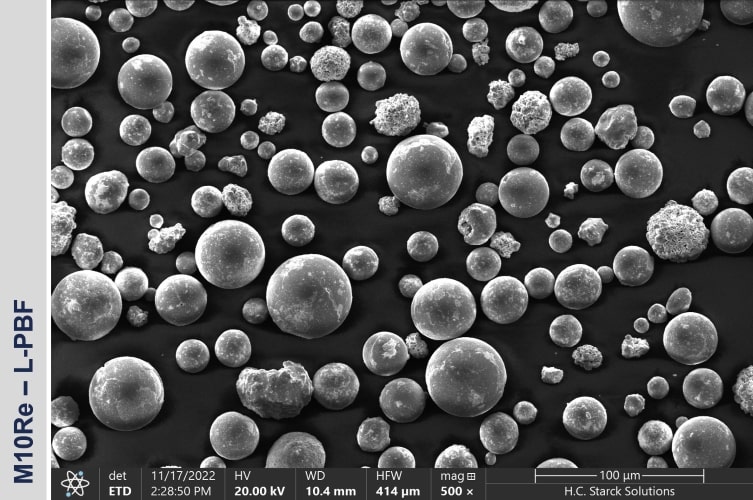

Our MoRe additive manufacturing powder is engineered for seamless, reliable printing, featuring low oxygen content, excellent flow properties, and high apparent and tap densities. Designed to excel in extreme environments, it delivers high thermal conductivity, superior corrosion resistance, low thermal expansion, and remarkable strength at elevated temperatures. This custom-engineered alloy powder tackles complex challenges with unmatched quality and performance.

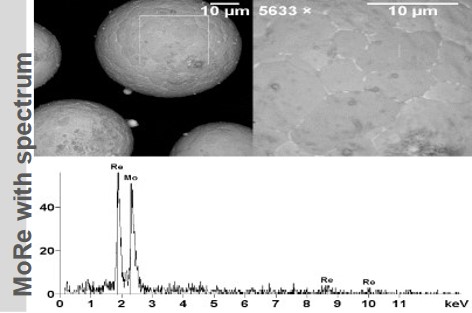

Molybdenum RHenium Additive Manufacturing Chemical Characteristics

| Element | Percent% |

| Mo2 | 90 – 52 |

| Re2 | 10 – 48 |

| O | < 0.05 |

| C | < 0.01 |

Molybdenum RHenium Additive Manufacturing Physical Characteristics

| Property | DED | L-PBF |

| Bulk density, g/cc | > 5.2 | > 5.2 |

| Flow, s/50g | < 14 | < 12 |

| PSD, d10, µm | > 40 | > 10 |

| PSD, d90, µm | < 150 | < 53 |

Key Benefits of Mo-Re Additive manufacturing Powder

- Thermal Efficiency

- Exceptional conductivity and minimal expansion make it ideal for high-temperature applications.

- Corrosion Resistance

- Built to withstand tough environments, ensuring long-lasting durability.

- High Purity

- Low oxygen content ensures precision and reliability in every use.

- Precision Manufacturing

- Designed for industries like aerospace, medical, defense, and energy.

- Enhanced Efficiency

- Outstanding flowability and density minimize material waste.

Molybdenum Additive manufacturing Powders

| Powder Grades | Chemistry | Size | Other Notes |

| MoRe | Mo10, 41, 48 Re | L-PBF and DED | Available upon request |

| Mo-TZM | 0.5%Ti – 0.1% Zr | L-PBF and DED | – |

| Mo-HfC | 1% Hf | L-PBF and DED | Also made as Mo7ReHfC |

| Mo-La | 1.2% La2O3 | L-PBF and DED | Under development |

Precision Metal capabilities at Elmet Technologies

At Elmet Technologies, we specialize in refractory metal powders, delivering customized powder feedstock and cutting-edge additive manufacturing processes. We are committed to providing top-quality, precision-engineered materials for even the most challenging applications. Our capabilities also extend to extrusion, rotary forging, and both hot and cold rolling, offering a complete range of refractory metal solutions.