C103 Additive Manufacturing Powder

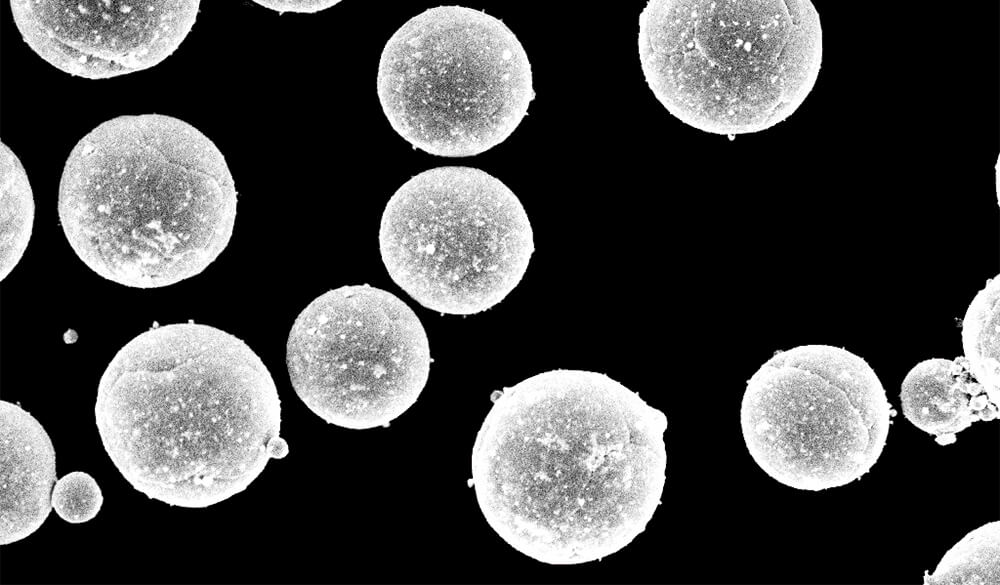

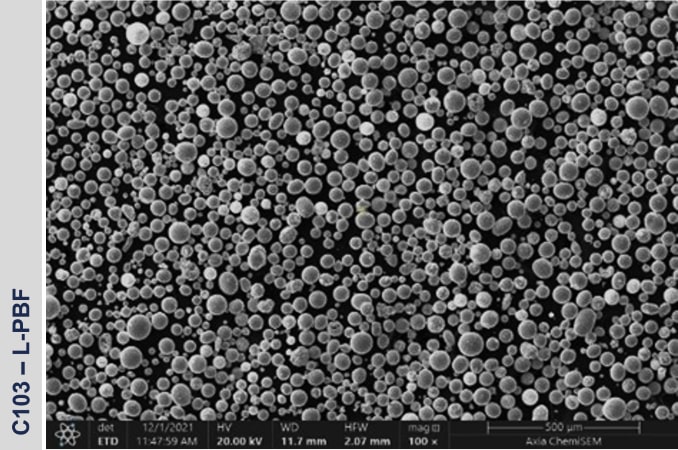

Elmet Technologies proudly offers C103 additive manufacturing powder, meticulously designed for laser-powder bed fusion (L-PBF) processes. Engineered for high performance, this powder boasts low oxygen content, excellent flowability, and superior apparent and tap densities. These features make it an ideal solution for demanding applications in rocket and jet propulsion systems, such as spacecraft and launch vehicles.

One of the standout advantages of C103 AM powder is its exceptional strength, remaining highly effective at extreme temperatures of up to 2700°F (1482°C). Additionally, this advanced material exhibits remarkable resistance to high-frequency vibrations, even under cryogenic conditions. Its low ductile-to-brittle transition temperature further enhances its reliability, making it a top choice for critical satellite applications.

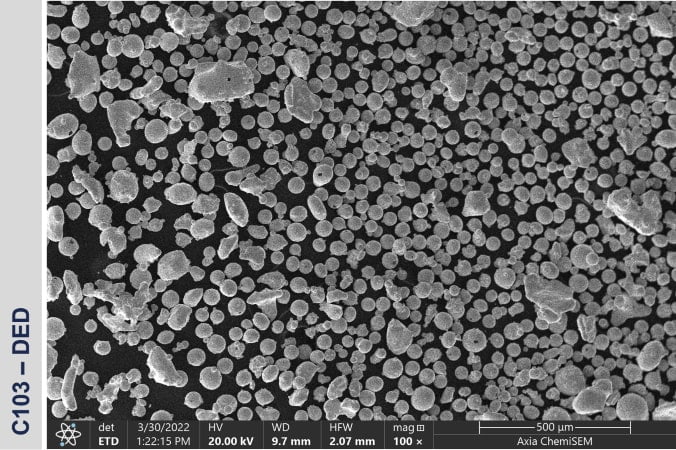

C103 Additive Powder Physical Characteristics

| Property | DED | L-PBF |

| Flow, s/50g | < 17 | < 15 |

| Bulk density, g/cc | > 4.5 | > 4.5 |

| PSD, d10, µm | > 40 | > 10 |

| PSD, d90, µm | < 150 | < 53 |

C103 Additive Powder Chemical Characteristics

| Element | Percent % |

| Nb | 88 min |

| Hf | 9 – 11 |

| Ti | 0.7 – 1.3 |

| Ta | 0.5 max |

| W | 0.5 max |

| Zr | 0.7 max |

| C | 0.015 max |

| O | 0.05 max |

3D Printing with c103 AM Powder

Manufacturers increasingly use Nb-Hf-Ti AM powder for 3D printing due to its:

- Impressive Corrosion Resistance: Long-lasting performance in harsh conditions.

- Robust Mechanical Properties: Delivers strength and reliability in demanding uses.

- Exceptional Heat Resistance: Performs reliably in high-temperature environments.

- Outstanding Ductility: Enables versatility and the creation of intricate, complex shapes.

- Strength & Lightweight Properties: Combines durability with reduced weight for diverse applications.

This adaptable material is driving technological advancements and innovation in additive manufacturing.

High-Performance C103 Additive Powder

Our C103 additive manufacturing powder is precisely formulated with an optimized blend of niobium, hafnium, titanium, and other key elements. Produced using a cutting-edge process, it ensures a uniform microstructure and tightly controlled characteristics. Known for its lightweight and refractory properties, C103 excels in extreme environments. It is a reliable material for thruster nozzles and leading edges, making it a top choice in aerospace and defense applications.

c103 and related Powders for Additive manufacturing

| Powder Grades | Chemistry | Size | Other Notes |

| Nb-C103 | 9 – 11% Hf, 0.7 – 1.3%Ti | L-PBF | Excellent flowability, typically 300ppm O2 |

| Nb | > 99.9% | L-PBF and DED | < 600ppm O2 |

| Other Nb Alloys | FS-85 | FS-85 (Nb-28%Ta-10%W-1%Zr) |

Your Partner in Refractory Metal Solutions

Elmet Technologies is a fully integrated company based in the US, operating large facilities in Maine, Ohio, and Michigan. We provide a wide range of products and specialized services, including extrusion, rotary forging, hot and cold rolling, and additive manufacturing, delivering comprehensive refractory metal solutions.