Capabilities

Elmet Technologies continues to expand its powder metallurgy capabilities with advanced manufacturing technology and new processing techniques. We have been continuously enhancing our methods for improving the production of refractory metal products since 1929. Through every step of the manufacturing process, new methods of consolidation, thermomechanical processing, machining, and final inspection are evaluated for continuous improvement and advancement.

Our advanced powder processing techniques and full-service analytical laboratories meet the most rigorous standards in the industry. We offer custom formulations and powder blending with precise performance testing for every batch of powder we produce. With a commitment to innovation, reliability, and customer satisfaction, Elmet Technologies leads the way in providing high-performance powder solutions that enable our customers to achieve their goals.

high-performance starts with high quality

With metal parts, performance begins with the powder. Our fully-integrated manufacturing capabilities help transform powders into end products. By utilizing highly-specialized reduction techniques, forming processes, and mechanical processing methods, we turn complex powders into high-performance parts. Every innovation traces back to the integrity of the starting materials.

Advanced Powder Metallurgy Capabilities

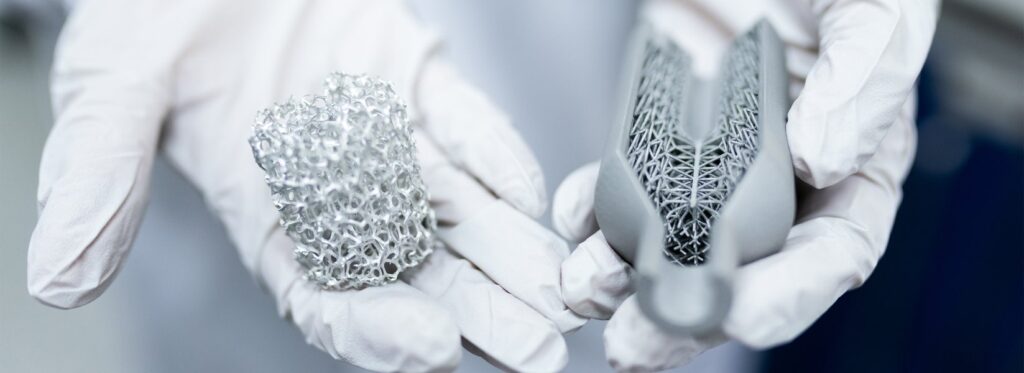

Elmet Technologies offers advanced powder metallurgy techniques for the production of ultrapure refractory metal powders and extremely high-performance alloys. Our capabilities include: powder production, pressing and sintering, hot isostatic pressing, direct extrusion, and more. We also utilize an array of innovative AM technologies to produce powder and wire feedstocks that offer world-class performance with highly spherical powder morphology, excellent flowability, exceptional reproducibility, and high purity levels. We continue to grow through our commitment to innovation and continuous improvement.

Comprehensive Analytical Laboratories

Our analytical laboratories enable precise control of our powder metallurgy capabilities, providing precise material characterization and validation at every stage of production. With advanced instrumentation and rigorous testing protocols, we ensure powders and finished components meet the most demanding performance, purity, and consistency requirements. Our laboratories are driving innovation through data-driven process optimization with detailed insights into powder structures.

innovative refractory metal Manufacturing

Elmet Technologies continues to innovate and utilize novel approaches for manufacturing refractory metals. Our production capabilities and metal manufacturing techniques includes:

- Toll Services: extrusion, rotary forging, hot rolling, cold rolling, and more

- Powder Metallurgy: powder reduction, pressing, sintering, mechanical processing

- Alloy Development: extensive capabilities for developing high-performance alloys

- Engineering & Modeling: thermomechanical processing and thermodynamic analysis

- AM Technology: 3D screen printing, laser powder bed fusion (L-PBF), additive powders

- Advanced Machining and Fabrication: transforming powders into finished components

Your Partner in Powder Metallurgy Solutions

Elmet Technologies is your dedicated partner in powder metallurgy solutions. We often develop new innovations in close collaboration with our customers. Our team of experts is continuously examining the properties of our materials to push the boundaries of engineering and technology. With a commitment to ongoing research and development, we continue to design, produce, and manipulate metal powders to help our customers achieve breakthrough performance in critical applications.