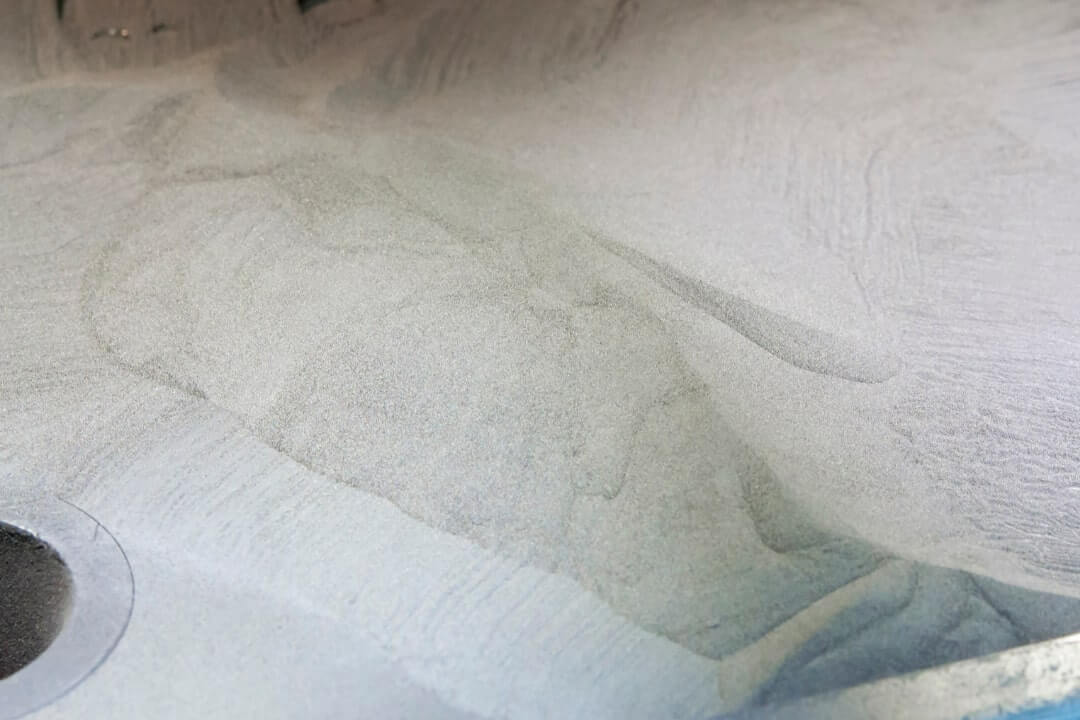

Tantalum tungsten Additive Manufacturing Powder

Elmet Technologies manufactures tantalum tungsten additive manufacturing powder, tailored for the most challenging applications. Our cutting-edge additive manufacturing techniques allow for the production of custom components with exceptional accuracy, driving advancements in industries like aerospace, medical, energy, and industrial sectors. Tantalum and its alloys are at the forefront of additive manufacturing, offering outstanding durability, resistance to corrosion, and superior performance under high temperatures for mission-critical applications.

Tantalum offers adaptability in additive manufacturing, transforming the way components are produced. Using methods like laser-powder bed fusion (L-PBF), tantalum can be manufactured into intricate designs with remarkable precision. Tantalum tungsten alloys take this step further by combining tantalum’s excellent corrosion resistance with tungsten’s high strength and thermal stability. Tantalum tungsten powders deliver extreme durability, wear resistance, and functionality at temperatures over 3,000°C, ideal for heat exchangers, reactor vessels, radiation shielding, and aerospace propulsion.

Tantalum Powders for AM

| Powder Grades | Chemistry | Size | Other Notes |

| TaW | 2.5 – 10% W | L-PBF and DED | DED size potentially available |

| Ta | > 99.9% | L-PBF and DED | < 500ppm O2 |

Tantalum tungsten Additive Manufacturing Powder

Exceptional Powder Quality

- Spray drying ensures consistent flowability and uniformity.

- Ideal for additive manufacturing, delivering precise and dependable results.

Plasma Densified for Enhanced Performance

- Increased density supports excellent mechanical properties.

- Removes impurities to deliver outstanding purity and reliability.

Why Tantalum Excels in Extreme Conditions

Tantalum offers exceptional mechanical strength, durability, and resistance to high temperatures, making it an ideal choice for aerospace and defense applications. Its unique properties are suited for high-performance uses such as rocket nozzles, counterbalance weights, fragmentation warheads, and specialized defense and aerospace components.

Key Uses of Tantalum in Advanced Manufacturing

Tantalum stands out as an exceptional material, combining unmatched corrosion resistance, remarkable durability, excellent heat transfer properties, and superior workability. These qualities make it ideal for even the most challenging industrial applications, including processes such as annealing, brazing, sintering, heat treating, and other high-temperature operations.

Common products manufactured with tantalum include:

- Heat exchangers

- Heating elements

- Crucibles

- Pipe spools

- Components for corrosive fluids

- Coils

- Condensers

- Complex furnace parts

- Other custom-engineered components

Outstanding Corrosion Resistance and Durability

Tantalum offers unmatched longevity and maintenance-free durability, making it the most cost-efficient choice for corrosion protection in even the toughest applications. Its near-complete resistance to chemical attack ensures consistent performance across a wide variety of extreme oxidizing and reducing environments.

Biomedical Applications of Tantalum

Tantalum’s unique ability to form porous structures greatly improves bone osteointegration, enabling exceptional biological integration. Its customizable properties make it ideal for designing precise implants, while its lightweight composition reduces mass without sacrificing strength or durability.

Examples of potential applications include:

- Cardiovascular stents

- Radiation imaging markers

- Orthopedic, dental, and spinal implants

Biomedical Screws

Trusted U.S. Manufacturing Across All Facilities

Our U.S.-based production facilities deliver exceptional quality, ensure strict traceability, and adhere to the highest industry standards. We follow certified processes to reliably and precisely meet the demands of your most complex projects.