Molybdenum Additive Manufacturing Powder

Elmet Technologies specializes in producing high-quality molybdenum additive manufacturing powder, designed for 3D printing processes. Our molybdenum AM powders are designed for superior performance, offering high-temperature strength, exceptional corrosion resistance, minimal thermal expansion, and excellent thermal conductivity. With low oxygen levels, superior flowability, and high apparent and tap densities, our molybdenum AM powders are a reliable material used in a wide range of industries and applications.

Molybdenum offers low density making it ideal for lightweight applications that demand strength and durability. At Elmet, we ensure unmatched precision in our manufacturing processes, producing high-quality molybdenum and molybdenum alloy powders with tightly controlled particle sizes, ranging from 3 to 30 µm.

Molybdenum Additive manufacturing Chemical Characteristics

| Element | Percent% |

| Mo | 99.9 min |

| O | < 0.03 |

| C | < 0.01 |

Molybdenum Additive Manufacturing Physical Characteristics

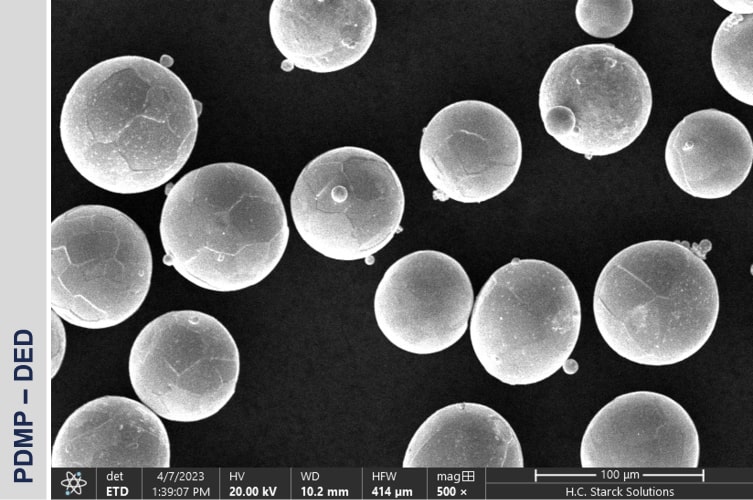

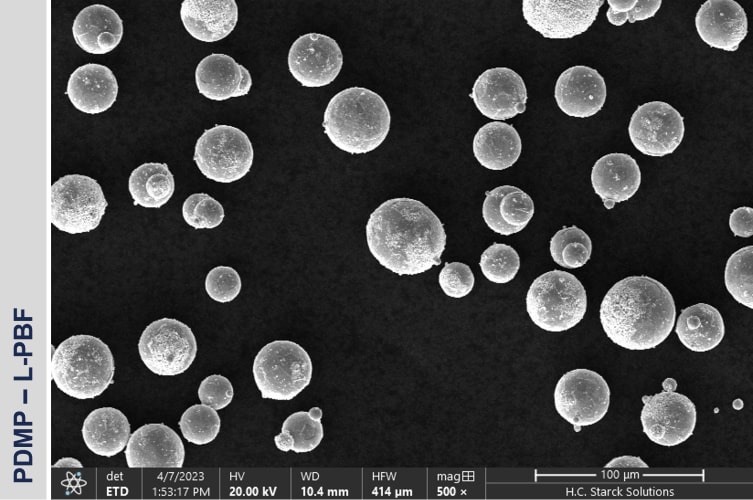

| Property | DED | L-PBF |

| Bulk density, g/cc | > 5.2 | > 5.2 |

| Flow, s/50g | < 14 | < 12 |

| PSD, d10, µm | > 40 | > 10 |

| PSD, d90, µm | < 150 | < 53 |

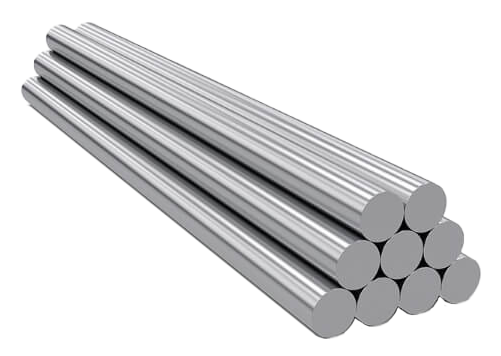

High Quality Molybdenum Components

- Rod: Elmet manufactures and stocks molybdenum rods in standard sizes, ideal for applications such as semiconductors, lighting, and high-reliability diodes.

- Wire: We produce molybdenum, potassium-doped molybdenum HCT wires, with diameters as small as 0.0007″.

- Plate: Elmet provides high-quality molybdenum plate, customizable in thickness, size, length, and surface finish.

- Foil: Our foil is available in standard thicknesses ranging from .001″ to .005″ (and thicker), fully customizable in size, thickness, length, and other properties.

- Sheet: Starting from metal powder, Elmet produces cold-rolled sheet in various thicknesses and lengths, perfectly tailored to your needs.

- Precision Machined Components: With decades of expertise, Elmet offers advanced molybdenum machining with over 70 cutting-edge machines.

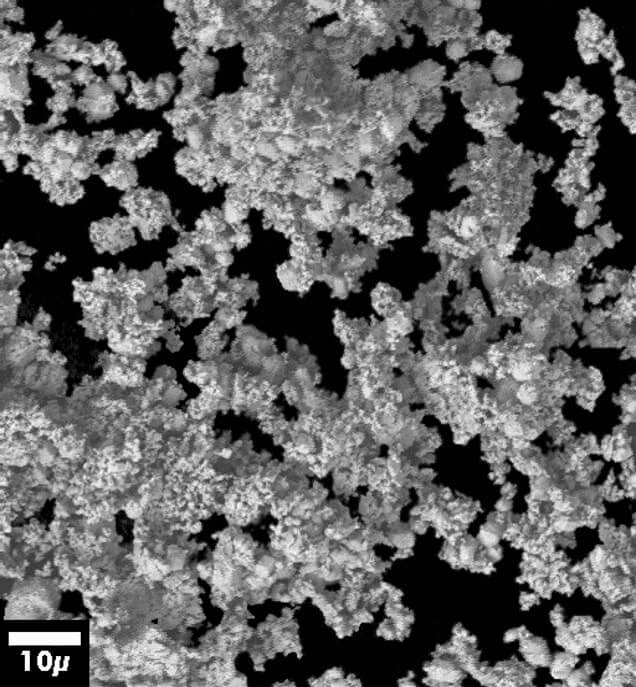

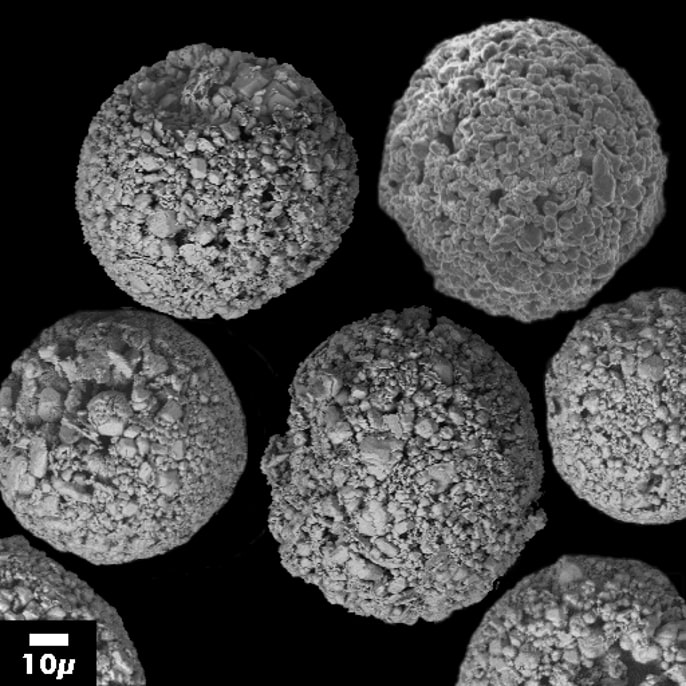

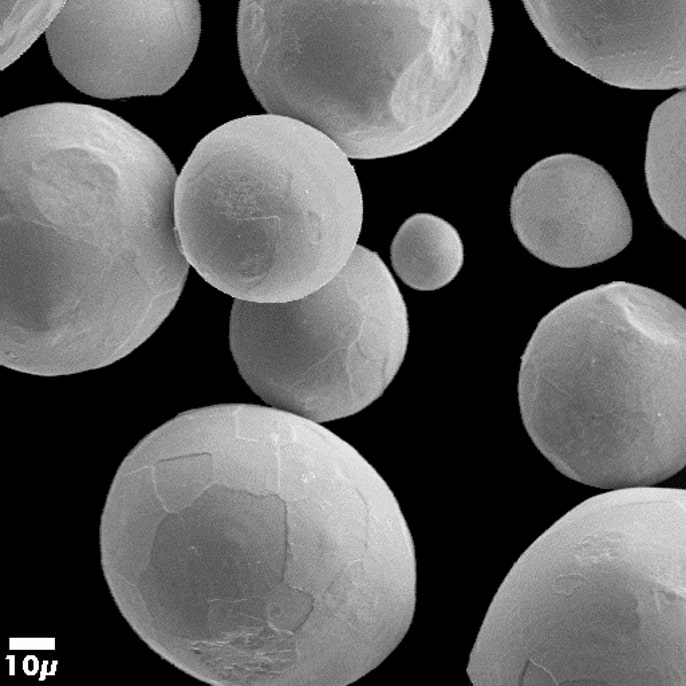

MO Powder Production Spray Dry & Plasma Densification

| Incoming Mo powder | Spray Dry Process | Spray Dry Powder | Plasma Process | Plasma Densified Powder |

|---|---|---|---|---|

| Mo feedstock no flow 1 – 50µm size, 1.2 g/cc density | Spray drying atomizes and dries slurry to spheres. | Spheres 25 s/50g flow 20 – 100µm size 2.5g/cc density | Melts spray dried powder in 20,000° flame | Fully dense spheres 10 s/50g flow 10 – 100µm size >5g/cc density |

Customized Molybdenum Solutions for Precision Engineering

Advanced engineering techniques like additive manufacturing and powder metallurgy utilize processes such as isostatic pressing and metal injection molding to produce high-performance parts. At Elmet Technologies, we provide top-quality molybdenum additive manufacturing powders specifically designed for these applications.

Our powders, featuring precisely controlled particle sizes ranging from 3 to 30 microns, deliver the accuracy and reliability required in AM methods. Their tailored properties ensure dependable performance in even the toughest conditions.

Molybdenum Powders for Additive manufacturing

| Powder Grades | Hall Flow Rate (s/50g) | Bulk Density (g/cc) | Particle Size D10 (mm) | Particle Size D50 (mm) | Particle Size D90 (mm) |

| PDMP – DED (40 – 150 µm) | < 17 | > 5 | > 40 | 65- 75 | < 150 |

| PDMP – L-PBF (10 – 50 µm) | < 15 | > 5 | > 10 | 25 – 35 | < 50 |

Molybednum Facts & Figures

- Symbol: Mo

- Classification: Transition metal, Group VI

- Atomic Number: 42

- Density: 10.28 g/cm³

- Year of Discovery: 1778

- Melting Point: 2620 °C

- Heat Resistance: Supports loads up to 1600 °C

- Conductivity: Outstanding thermal and electrical performance

- Vapor Pressure: Low, even at elevated temperatures

- Thermal Expansion: Minimal expansion coefficient

- Corrosion Resistance: Highly resistant

- Energy Shielding: Provides excellent protection against high-energy exposure

Advantages of Additive Manufacturing with Molybdenum

Additive manufacturing is revolutionizing the production of intricate molybdenum components, meeting the growing demands of complex designs across various industries. Molybdenum additive manufacturing powder is perfectly suited for this process due to its exceptional alloying potential, high flowability for 3D printing, and outstanding heat resistance. Its compatibility with advanced techniques like Laser-Powder Bed Fusion (L-PBF) and Directed Energy Deposition (DED) ensures the efficient production of high-performance, reliable parts.