Tungsten Additive Manufacturing Powder

Elmet Technologies is the only US-owned, fully integrated manufacturer of tungsten additive manufacturing powder. We specialize in producing powders designed specifically for laser powder bed fusion (L-PBF) additive manufacturing processes. Our tungsten powders are known for their low oxygen content, superior flowability, and high apparent and tap densities. With tungsten being the element with the highest melting point, it is an ideal material for challenging applications in industries like aerospace and defense. Its high density and superior radiation shielding also make tungsten ideal for producing compact, high-precision collimators used in medical and nuclear imaging.

Additive manufacturing with tungsten offers numerous benefits, including the ability to produce intricate geometries, combine multiple components into one, customize designs, accelerate production, and reduce material waste. As specialists in powder metallurgy, we develop custom powder formulations tailored to meet our customers’ unique requirements. Our fully integrated production process enables precise control over material properties such as hardness, ductility, tensile strength, and grain size, ensuring alignment with specific application needs. This approach also streamlines production by consolidating parts and reducing the need for multiple components.

Chemical Characteristics

| Element | Percent% |

| W | 99.9 min |

| O | < 0.03 |

| C | < 0.01 |

Physical Characteristics

| Property | DED | L-PBF |

| Bulk density, g/cc | > 10 | > 10 |

| Flow, s/50g | < 80 | < 7 |

| PSD, d10, µm | > 40 | > 10 |

| PSD, d90, µm | < 150 | < 53 |

Custom chemistry can be provided upon request. The printed material meets all property requirements outlined in ASTM B777 specifications.

Advantages of Tungsten Additive Manufacturing Powder

- Customization: Materials can be tailored to meet the exact needs of specific applications, providing highly specialized solutions.

- Intricate Designs: Enables the creation of complex shapes and structures that traditional casting or machining cannot achieve.

- Reduced Waste: The powder is recyclable during manufacturing, helping to minimize material waste.

- Faster Production: Shortens development timelines compared to traditional manufacturing methods.

- Simplified Assembly: Combines multiple parts into a single component, reducing the need for additional assembly steps.

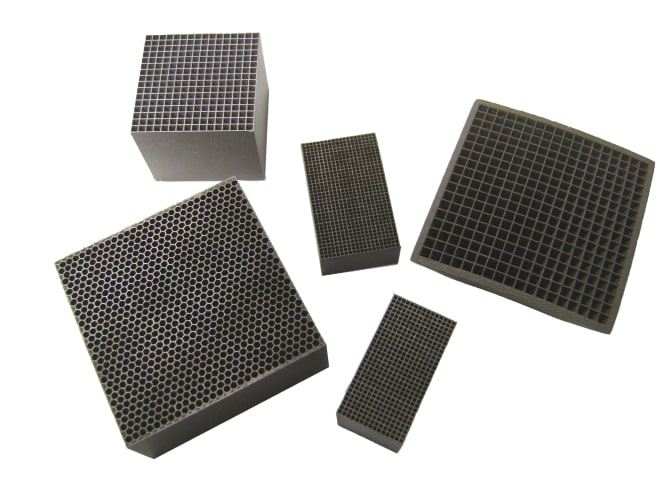

Tungsten AM Powders for radiation shielding

Elmet Technologies provides premium tungsten additive manufacturing powder, ideal for producing high-precision collimators used in medical and nuclear imaging. Due to tungsten’s high density and superior radiation shielding properties, it enables the design of more compact and efficient collimators. Using advanced techniques like 3D printing, Elmet creates intricate tungsten alloy components with exceptional precision, meeting even the most demanding specifications.

Pure Tungsten Powders

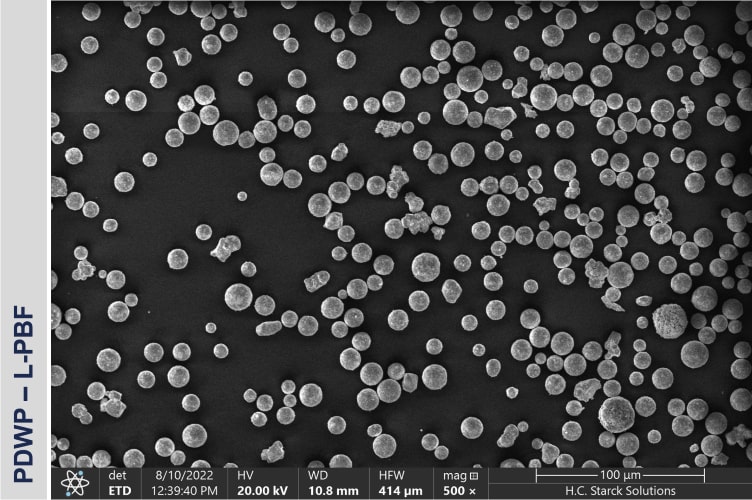

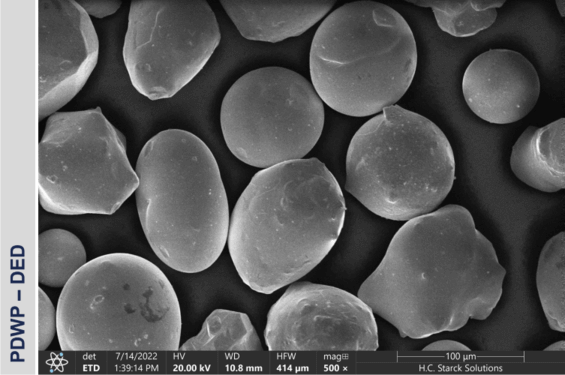

| W Powder Grades | Hall Flow Rate (s/50g) | Bulk Density (g/cc) | Particle Size D10 (mm) | Particle Size D50 (mm) | Particle Size D90 (mm) |

| PDWP – DED (40 – 150 µm) | < 6 | > 10 | > 40 | 70- 80 | < 150 |

| PDWP – L-PBF (10 – 50 µm) | < 6 | > 10 | > 10 | 25 – 35 | < 50 |

Tungsten Material Facts & Figures

- Symbol: W

- Atomic Number: 74

- Density: 19.25 g / cm3

- Transition Metal, Group VI

- Discovered: 1781

- Melting Point: 3420 °C, highest metal, 2nd highest of elements

- High density

- Low vapor pressure

- Elastic modulus

- High Electrical resistance

- Strong corrosion resistance

- Low coefficient of thermal expansion (CTE)

High-Quality Powder Metallurgy Solutions

Elmet Technologies is a recognized leader in advanced powder solutions, offering a comprehensive suite of services such as powder blending, spray drying, plasma densification, and alloy development. With deep expertise in powder metallurgy and a commitment to innovation, we deliver high-quality powders tailored to meet the diverse needs of various applications. By prioritizing research and taking an integrated approach, Elmet stands as a trusted partner for reliable, customized powder solutions that drive performance and precision.