Ready-To-Press Molybdenum Powder

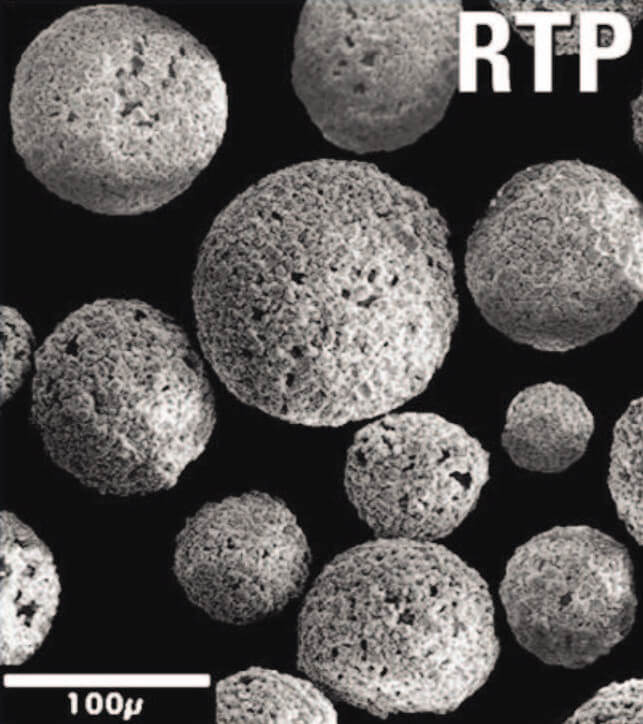

Elmet Technologies provides ready-to-press molybdenum powder, known as RTP, for uniform mold filling and high pressed and sintered density. RTP is a uniformly agglomerated Mo powder with organic binder. The agglomerates are porous spheres and are free flowing. As a leading manufacturer of high-performance refractory metal powders, Elmet Technologies offers one of the most comprehensive powder metallurgy product portfolios ever assembled.

Our ready-to-press molybdenum powder is enhanced with wax, providing a streamlined, high-quality solution for industries requiring consistent density and strength. Its easy-to-use, flowable formulation and high green strength enables manufacturers to simplify production processes, achieving more precise results, all while minimize material waste. These benefits make RTP Powder an ideal choice for high-performance applications, even those with challenging environments.

Key Characteristics of Ready-to-press POwder

RTP Powder is spheroidized through spray drying, utilizing a suspension composed of fine pure molybdenum (Mo) powders and an organic binder (wax). Key features and uses include:

- High purity of 99.95%

- High sintered density

- Uniform mold filling

- Ready-to-press

Our team of experts is available to discuss custom materials and unique requirements.

Properties of Pure Molybdenum RTP Powder

Chemical Characteristics

Ready-To-Press Molybdenum Powder has a typical purity of >99.95%

(Mass fraction in % [cg/g]; ppm [μg/g])

| Mo (excluding O and C) | Min. | 99.95% |

| O | Max. | 1.1% |

| C | Max. | 1.1% |

Physical Characteristics

A key feature of RTP powder is its coarse particle size (-100+325)

| Apparent Density | Hall Flow |

|---|---|

| 1.6-2.3 g/cm3 (27-37 g/inch3) | Max. 35 s/50 g |

Sieve Analysis

| +150 μm (+100 mesh) | max. 2.5% |

| -45 μm (-325 mesh) | max. 10% |

Applications for ready-to-press molybdenum powder

Elmet Technologies manufactures its powders under strict quality control procedures for each application. RTP Powders offer high green strength with superior performance characteristics and exceptional material quality. They are well-suited for applications requiring consistent performance and process flexibility.

Powder Metallurgy

Metal Alloying

High Temperature Environments