Extra Fine Molybdenum Metal Powder

Elmet Technologies manufactures its extra fine molybdenum metal powder, OMPF, engineered for high-performance and ultra-precision applications. Its 99.8% minimum molybdenum content ensures unparalleled purity, critical for applications where even the smallest impurity can compromise product performance.

Produced meticulously from sublimed oxide in a single pass, the process ensures superior quality and consistency. Ideal for industries such as aerospace, electronics, and advanced manufacturing, this extra fine powder is the trusted choice for applications demanding unmatched reliability and precision.

high-quality Fine Molybdenum Metal Powder

Elmet Technologies utilizes unique powder metallurgy techniques to manufacture its extra fine molybdenum metal powder, known as OMPF. Manufacturers use this top-tier powder in critical applications, such as catalysts, conductive inks, and alloy enhancements. Its high surface area also makes it ideal for specialized uses in propylene oxide catalyst powders, among others.

High-Performance OmPF Powder

We offer an extensive selection of high-performance powders, available in a wide range of sizes and purities to meet your specific requirements. Our powders are designed to deliver exceptional quality and performance, making them ideal for a variety of applications. Speak with our team of powder metallurgy experts to learn how our extra fine molybdenum metal powder, OMPF, can optimize your process or application.

Extra Fine Molybdenum Metal Powder: OMPF

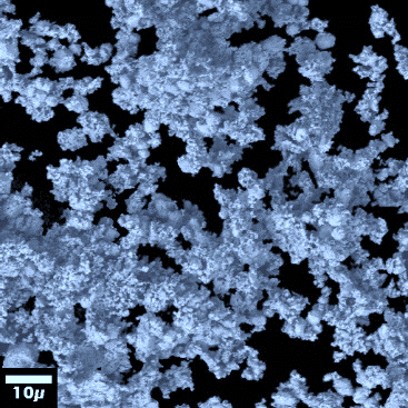

Physical Characteristics

OMPF powder is formed by starting with sublimed oxide. Afterward, we run through our proprietary single-pass process.

| Mesh Size | Fisher Number (as supplied) | Apparent Density |

|---|---|---|

| -250 μm (-60 mesh)* | 1.5 -3.0 μm | Min. 0.6 g/cm3 (min. 10 g/inch3) |

Chemical Characteristics of OMPF Powder

OMPF powder has a high purity and is comparatively the finest FSSS# powder from Elmet.

(Mass fraction in % [cg/g]; ppm [μg/g])

| Mo (excluding gases) | 99.8% min |

| O | 0.150% max |

| Cr | 0.010% max |

| Fe | 0.040% max |

| Mg | 0.002% max |

| Ni | 0.020% max |

| Si | 0.025% max |

| Sn | 0.008% max |