Molybdenum Powder

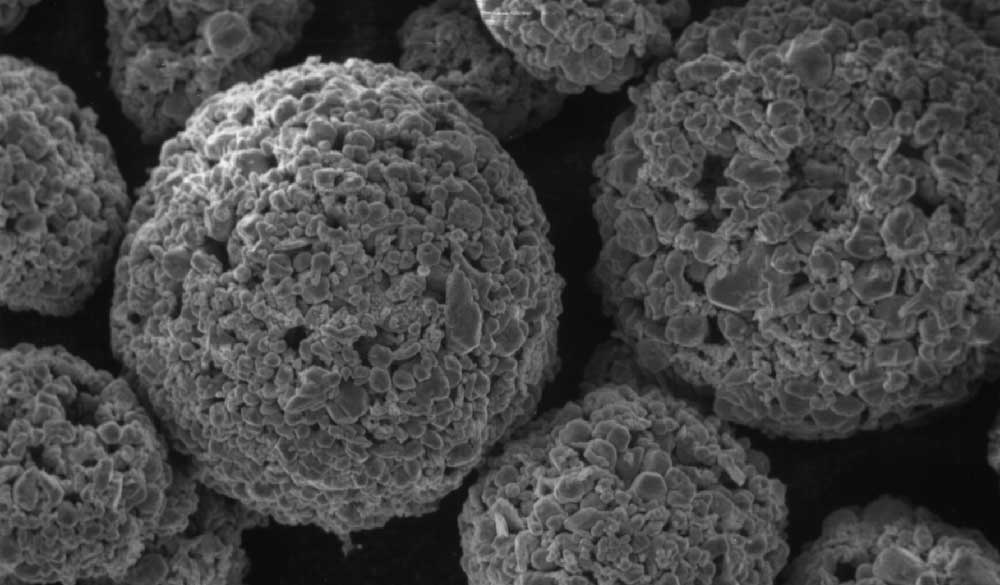

Elmet Technologies is a leading US-based manufacturer specializing in advanced molybdenum powder metallurgy solutions. With decades of expertise and a fully integrated production process, we custom-formulate molybdenum powders to meet the unique requirements of our customers. By optimizing particle sizes, adjusting green strengths, and crafting diverse agglomerated grain structures, we ensure our powders are tailored per each unique application requirement.

Our molybdenum powders are produced with exceptional purity, exceeding 99.95%, and are available in various forms, including thermal spray powders, blended alloy powders, and oxide dispersion-strengthened alloys. Serving industries such as aerospace, defense, electronics, medical, and industrial processing, Elmet Technologies is committed to delivering high-performance solutions that meet stringent specifications and exceed customer expectations.

High Purity Molybdenum powder

Elmet Technologies has extensive molybdenum powder production capabilities to meet stringent specifications for our customers. We produce Mo powders from molybdenum trioxide and ammonium molybdates using hydrogen reduction. We control input materials and reduction parameters to achieve purity above 99.95% with low residual oxygen and carbon content.

Particle size can be controlled through screening and other techniques from coarse fractions of -5 mesh (4 mm) to -325 mesh (-45 µm). Additional molybdenum alloy powders are available, such as TZM (Mo-0.5Ti-0.1Zr) and MHC (Mo-1.2Hf-0.1C), or oxide dispersion strengthened alloys, such as MoLa (Mo-1.0La2O3). Custom alloys are available per customer request.

Your Partner in Molybdenum Powder

As a world leader in developing and manufacturing high-performance molybdenum powder, Elmet Technologies offers the most comprehensive portfolio available, with size and purity options to match unique requirements.

Elmet offers advanced metallurgical processing and superior technical expertise, allowing us to consistently exceed customer expectations. We offer a full suite of tailor-made, high-performance molybdenum powders suitable for a wide range of customer uses.

Applications For Molybdenum Powder

- Alloying

- Brake pads

- Ceramic metallization

- Chemical catalyst

- Detonation initiator

- Diamond tooling

- Electronics

- Heating elements

- Metal matrix composites

- Infiltration

- Metal injection molding

- Photovoltaics

- Pressed and sintered ingots

- Pressed and sintered shapes

- Thermal spray technology

molybdenum Powders for Critical Applications

Elmet Technologies is a leading manufacturer of high-performance molybdenum powder and material solutions. With three U.S. facilities in Lewiston, Maine, Euclid, Ohio, and Coldwater, Michigan, we deliver precision-engineered products to meet diverse industry needs.

Our advanced manufacturing capabilities and innovative processes enable us to provide tailored solutions for specialized applications. Backed by decades of expertise, Elmet is committed to advancing manufacturing standards and exceeding customer expectations.

Physical Properties of Molybdenum Powder

| Typical Ranges | Particle Size Distribution | ||||

|---|---|---|---|---|---|

| Standard Screen Mesh | μm | FSSS# (μm) | Bulk | Tap (g/cc) | D10 | D50 | D90 (μm) | Product Data Sheet | |

| MoMP | -230 | <63 | 3.5-5.5 | 1.0-2.0 | 2.5-4.0 | 10 | 20 | 40 | 8010 |

| OMP | -200 | <75 | 2.5-3.5 | 1.0-2.0 | >2.0 | 7 | 15 | 45 | 800450 |

| OMPF | -230 | <63 | 1.8-2.5 | 1.0-1.5 | 2.0 | 4 | 10 | 40 | 8001 |

| MIMP-Type I | -500* | <25 | 3.5-5.5 | 2.0-3.5 | >3.0 | 2.5 | 5.5 | 13 | 8009 |

| MIMP-Type II | -635* <20 | 1.8-2.5 | 1.5-3.0 | >2.5 | 1.5 | 3.5 | 6 | 8009 |

| Mo2C | Customer Specific | 3.0-5.5 | 1.0-2.0 | >2.0 | 5 | 10 | 3 | – |

| RTP | -5-+325 | NA | 1.5-2.5 | NA | Flow s/50g <35s | 8005 |

| SOMP | Customer Specific | NA | >2.0 | NA | Flow s/50g <35s | 8006 |

| AM-Mo L-PBF | -50+15µm | NA | >5.2 | NA | Flow s/50g <12s | 7211 |

| AM-Mo DED | -150+40µ, | NA | <5.2 | NA | Flow s/50g <14s | 7211 |

| Spec Purity % | Potential Purity % | Typical Measurements (ppm) Oxygen | Cr | Fe | Mg | Ni | Si | Sn | Others | |

|---|---|---|---|---|

| MoMP | .>99.95 | >99.97 | <600 | 6 | 15 | 4 | 5 | 3 | 1| | Available Upon Request |

| OMP | >99.80 | >99.90 | <1000 | 10 | 60 | 5 | 10 | 100 | 3 | |

| OMPF | >99.80 | >99.90 | <1500 | 30 | 70 | 10 | 25 | 120 | 5 | |

| MIMP-Type I | >99.5 | >99.97 | <1500 | 6 | 20 | 4 | 5 | 3 | 1 | |

| MIMP-Type II | >99.80 | >99.90 | <2000 | 30 | 70 | 10 | 25 | 120 | 5 | |

| Mo2C | >93.00 | 5.5-6.5 C | NA | |

| RTP | >99.95 | >99.95 | ~1% O&C | 20 | 30 | 10 | 10 | 30 | 5 | |

| SOMP | >99.5 | >99.95 | O <1000; C <200 | |

| AM-Mo | >99.90 | >99.95 | O <250; C <50 |