Additive Manufacturing Powders

Elmet Technologies is a global leader in high-quality refractory metal powders, driving innovation in additive manufacturing. Our advanced additive manufacturing powders are essential for rapid prototyping and producing complex engineering components that are typically difficult to create with traditional methods.

These powders provide exceptional versatility, enabling the creation of intricate designs while offering a cost-effective solution for low-volume production. They are particularly beneficial for optimizing material usage, especially when working with expensive materials, making them a practical choice for numerous applications. With ongoing advancements in additive manufacturing powder and AM technology, their potential continues to grow, unlocking exciting possibilities in fields such as biomedical devices, propulsion systems, and thermal management solutions.

Our Additive Manufacturing Powders

We are always innovating with new materials and methods and are prepared to support your specific needs.

Additive Manufacturing Applications Provided

Laser – Powder Bed Fusion (L-PBF -50 + 10µm)

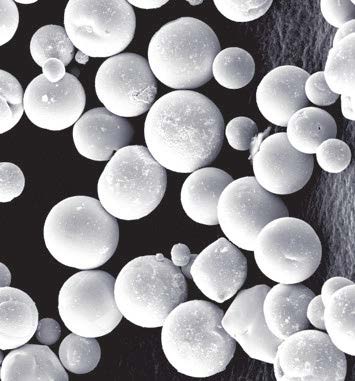

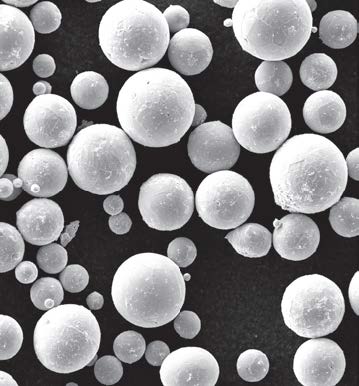

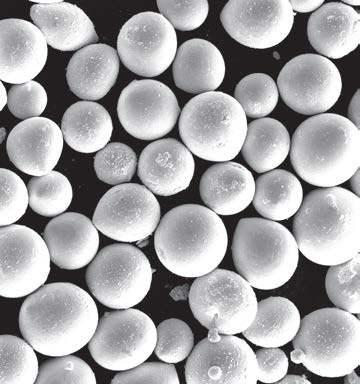

Laser Powder Bed Fusion is an advanced additive manufacturing process that uses a laser to precisely fuse layers of fine metal powder, producing exceptionally smooth and accurate components. At Elmet Technologies, we specialize in engineering custom powders to achieve high-density, premium-quality results across a wide range of applications.

- Materials for Production and R&D: W, WHA, WRe, Ta W, Mo, MoRe, Re, TZM, Nb, C103, Ta, Ta-5, 7.5, 10W

Powder Production Non-Reactive

Spray Dry / Plasma Densification

- Tungsten Heavy Alloy

- WRe (1,3,5,7,24, Re)

- TZM, MoLa, MoRe (10,41,48Re), MoHfC, MoReHfC

- Mo and alloys, W and alloys

- Classes 1,2,3 typically produced

Powder Production Reactive

Electrode Induction – Melting Gas Atomization (EIGA)

- L-PBF (-50 + 15µm) and DED (-150 + 40µm)

- Reactive metals – Ta, Nb, Nb-C103, Cb-752, FS-85

- High yield, low oxygen powder produced

- Uses melted ingots, extruded, and machined bars as feedstock

Advanced Refractory Metal Material

With cutting-edge manufacturing technology, a streamlined supply chain, and extensive metallurgical expertise, we create high-quality refractory metal feedstocks customized to your specific requirements. These feedstocks boast superior material properties and deliver peak performance, perfectly suited for the demanding needs of additive manufacturing.

Their properties exceed traditional production specifications and offer:

- High purity

- Low oxygen

- Spherical morphology

- Excellent flowability

- High bulk density

- Scalable volumes from lab to production

- Custom alloy development through R&D

- Century of refractory metal experience

- Customized PSD for specific printing methods

Additive Materials and Specifications

| Property | Unit | W | Mo | Ta | Nb |

| Purity | % | > 99.95 | > 99.95 | > 99.95 | > 99.95 |

| Mean Particle Size D50 | µm | 20 – 30 | 20 – 30 | 20 – 30 | 23 – 30 |

| D10/D90 | µm | 10/40 | 10/40 | 10/40 | 10/40 |

| Bulk Density | g/cc | 10 | 5 | 8 | 4 |

| Hall Flow | s/50g | 5 – 8 | 8 – 10 | 5 – 9 | 14 – 16 |

| Oxygen | ppm | 250 | 400 | 300 | 1500 |

Experts in Refractory metal Additive Manufacturing

At Elmet Technologies, we are committed to expanding our expertise and unlocking new possibilities for refractory metals. Our fully integrated supply chain, from powder production to finely post-processed components, ensures we deliver precision and performance to meet the most demanding customer requirements.

Partner with Elmet Technologies for cutting-edge additive manufacturing solutions in refractory metals, tailored to address the specific challenges of your industry.