Molybdenum Thermal Spray Powder

Elmet Technologies specializes in high-quality molybdenum thermal spray powder, engineered to boost surface performance and durability. Our spherical, flowable powders create uniform coatings that offer superior protection and restoration for diverse applications. We offer several types of molybdenum thermal spray powders, each known for exceptional wear resistance, heat resistance, and bonding capabilities, making them ideal for challenging environments. They are widely used in applications from large-area protective coatings to the refurbishment of small, precision-engineered metal components.

Our advanced powder metallurgy process ensures all thermal spray powders deposit evenly on substrates. This forms robust, contiguous layers that shield against harsh operating conditions, maintaining structural integrity and functionality in demanding environments. We deliver molybdenum thermal spray powders tailored to meet the technical requirements of industries like aerospace, automotive, and heavy equipment manufacturing.

oUR aDVANCED pOWDER mETALLURGY tECHNIQUES

Elmet Technologies specializes in developing high-performance molybdenum thermal spray powder tailored to meet a wide range of industry needs. As a global leader in thermal spray solutions, we offer a diverse and reliable product portfolio. Using advanced materials engineering and processing techniques, our powders deliver exceptional performance. We ensure precise control of particle size distribution (PSD), tailored powder morphology (irregular or spherical), consistent reproducibility, and high purity, all designed to excel in even the most demanding applications.

At Elmet, we specialize in tailoring particle properties to meet precise customer needs, offering everything from small-scale lab batches to high-volume production runs. This versatility enables us to serve industries that demand exceptional precision and quality. Our dedicated R&D services allow us to collaborate closely with clients to develop custom high-performance powders and alloys. These innovative solutions enhance the performance and durability of thermal spray coatings, ensuring superior protection and functionality for a wide range of surfaces and components.

HIGH-PERFORMANCE Molybdenum Thermal Spray Powders

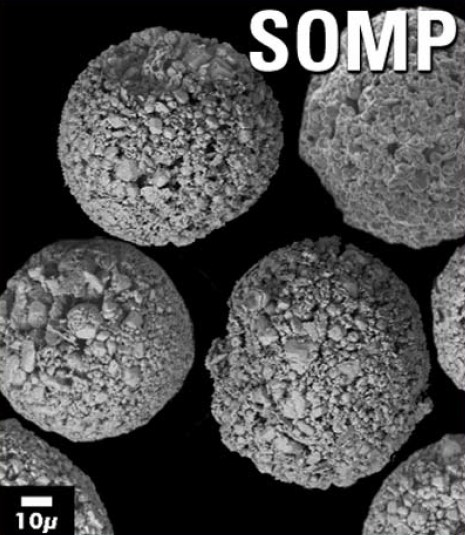

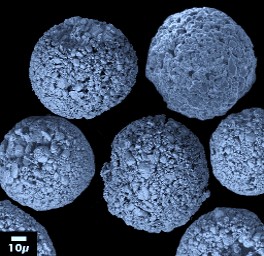

SOMP Powder

SOMP powder is a high-quality, advanced material designed to deliver exceptional performance in industrial applications. Featuring free-flowing, porous, spherical agglomerates, SOMP powder ensures reliability and efficiency in diverse thermal spray processes.

Available in both coarse and fine grades, SOMP powder meets a wide range of industry-specific needs, offering superior versatility across applications. Its engineered properties make it an excellent choice for creating durable, protective coatings and refurbishing intricate metal components.

SOMP Mo₂C Powder

Our SOMP Mo₂C High Carbon powder is designed for optimal performance in atmospheric plasma spraying. Its advanced formulation ensures reliable results, making it ideal for demanding industrial applications.

This high-carbon Mo-based powder is known for its durability, enabling the production of wear-resistant parts such as piston ring coatings and plastic extrusion screw flights, where superior wear resistance and long lifespan are essential.

MOLYBDENUM THERMAL SPRAY POWDER SPECIFICATIONS

Size Specifications

- Coarse Grade -170+325 mesh

- PWA 1313 -200+325

- Finest – PWA 1338

- Fine Grade -325 mesh

Chemical Characteristics

Mo (excluding gases) min. 99.8%

¹Mass fraction in % [cg/g]; ppm [μg/g]

Physical Characteristics

Apparent Density 30 g/cubic inch minimum

Hall flow 35 s/50 g maximum

Packaging

Powders from Elmet Technologies are typically shipped in non-returnable polyethylene-lined 20-liter (5-gallon) plastic pails or 60-liter (15-gallon) steel drums. We welcome special packaging inquiries.

Experts in Thermal Spray Powders

Elmet Technologies develops high-quality refractory metal powders for thermal spray applications. We use advanced deposition techniques, including plasma spraying, flame spraying, detonation spraying, high-velocity air fuel (HVAF), and high-velocity oxy-fuel (HVOF).

Our diverse spraying methods ensure precise and consistent application, delivering superior coating performance for various industrial needs. Elmet also offers carbon alloying capabilities, producing customized compositions, including pure Mo₂C with up to 6% carbon.

To meet unique specifications, we deliver additional customized alloy powder solutions, demonstrating our commitment to precision, versatility, and technical excellence.

Applications for Molybdenum Thermal Spray Powder

TRANSPORTATION

- Automobiles

- Trains

- Aircraft

- Boats

ENVIRONMENTAL

- Chemical plants

- Mining

- Earth moving equipment

- Power generation

FOOD PROCESSING

- Food manufacturing

- Food packaging