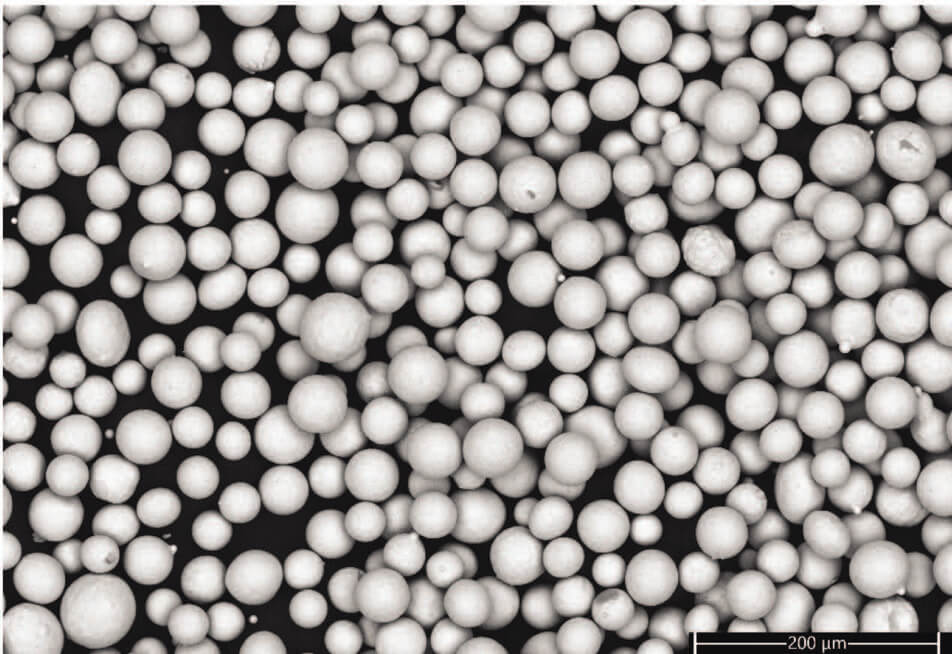

Titanium-Zirconium-Molybdenum Powder

Elmet Technologies specializes in Titanium-Zirconium-Molybdenum Powder, a premium-grade alloy designed for high-performance applications. Our TZM powder is composed of 0.50% titanium, 0.08% zirconium, and 0.03% carbon, with the balance molybdenum. This advanced Mo-based material surpasses pure molybdenum with superior mechanical and thermal properties, including enhanced weldability, strength, and the ability to withstand temperatures over 1300°C.

With its high melting point and exceptional thermal conductivity, TZM offers outstanding strength and durability. Its spherical morphology ensures excellent flowability and uniform distribution, making it ideal for AM processes. Featuring low oxygen content and superior flow characteristics, TZM materials and products also offer impressive corrosion resistance and reliability, making it the ideal material for high-temperature, demanding applications.

Common Titanium-Zirconium-Molybdenum Products

Elmet Technologies manufactures a wide range of Titanium-Zirconium-Molybdenum powder metallurgy products, components, and solutions, including:

Titanium-Zirconium-Molybdenum AM Powder: Specifications

Physical Properties

| Property | DED | L-PBF |

|---|---|---|

| Bulk density, g/cc | >5 | >5 |

| Flow, s/50g | <17 | <15 |

| PSD, d10, µm | >40 | >10 |

| PSD, d90, µm | <150 | <53 |

Chemical Properties

| Element | Percent |

|---|---|

| Mo | 99.2 min |

| Ti | 0.4-0.55 |

| Zr | 0.06-0.12 |

| C | <0.15 |

| O | <0.1 |

Benefits of titanium-zirconium-molybdenum powder

- Oxidation Resistance

- TZM boasts enhanced oxidation resistance.

- Resistance to Creep

- Exceptional in prolonged high-temperature environments.

- Durability and Strength

- Structural integrity retains under high-temperature conditions.

- High Melting Point

- An ideal solution for applications that require superior heat resistance.

Titanium-Zirconium-Molybdenum Powder Metallurgy Products

Titanium-Zirconium-Molybdenum (TZM) powder metallurgy products from Elmet Technologies include: rod, bar, sheet, plate, wire, AM powder, and more.

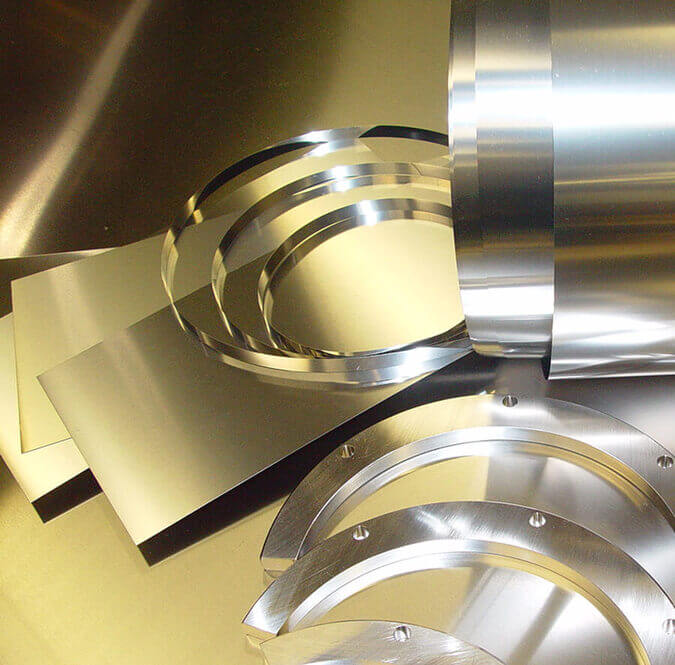

Sheet

We expertly produce cold-rolled TZM sheet in customizable thicknesses and lengths to meet your specific requirements.

The manufacturing process begins by pressing metal powder into ingots. The ingots then undergo sintering followed by hot rolling to form plates. The process culminates with precision cold rolling, transforming these plates into high-quality final sheet forms.

Rod

Our cold-rolled TZM rods offer high performance characteristics to meet diverse applications needs. Available in diameters ranging from 0.030″ to over 1.0″, we have capabilities to customize thickness, length, and surface finish.

We offer threaded, precision-machined, and gun-drilled choices, ensuring that the product aligns perfectly with your specifications. Our TZM rods undergo a process of pressing into ingots, sintering, swaging, and drawing. This ensures top performance and durability.

wire

Wire products are utilized in a wide variety of cutting-edge industries, including aerospace, medical equipment and devices, university research, lighting, electronics, and high-temperature furnaces.

Titanium-Zirconium-Molybdenum (TZM) wire is manufactured on an order-by-order basis.

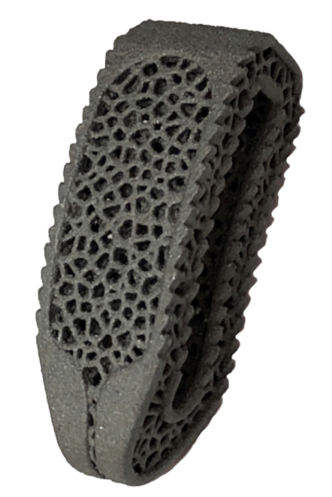

forging dies

TZM alloy is an ideal material for dies and tooling, due to its extraordinary strength at isothermal forging temperature.

The material is consolidated by powder metallurgy techniques. Forging dies, blanks, and billets are relied upon in the production of turbine blades, discs, vanes, hubs, rings, and more.