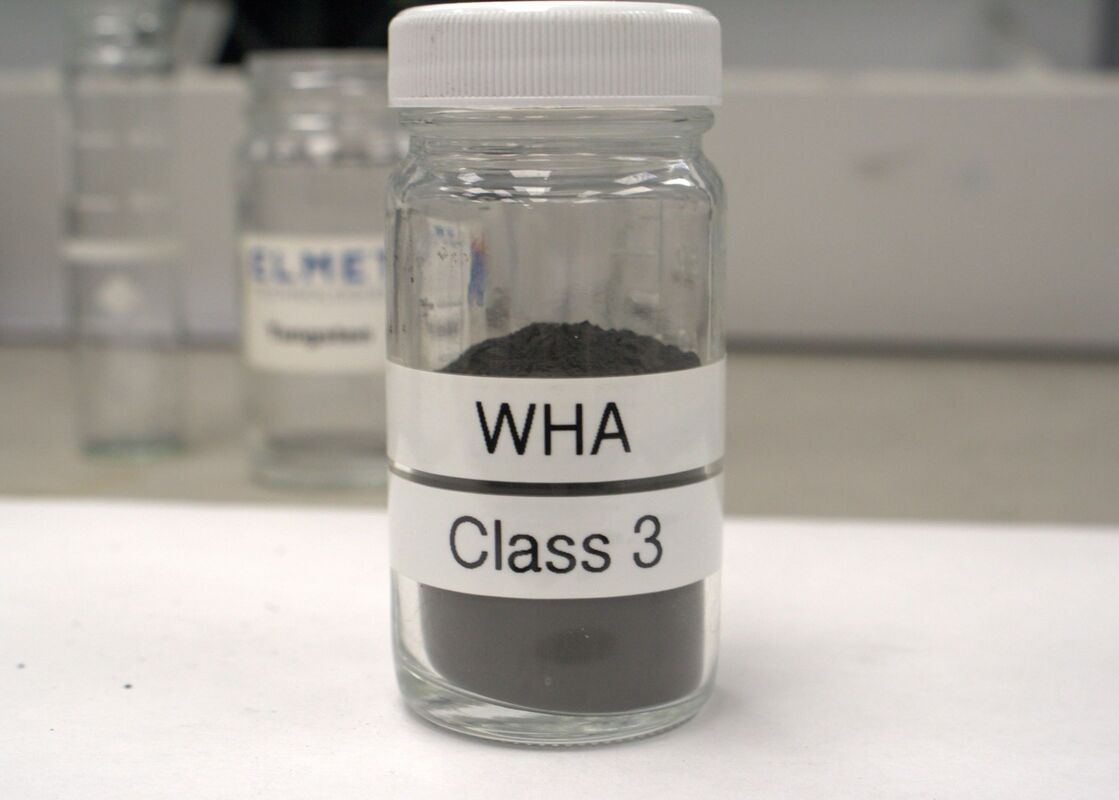

ASTM B777 CLASS 3 Powder

Elmet Technologies is proud to offer ASTM B777 Class 3 Powder, a high-density material that combines versatility with ease of production and machining, making it an ideal choice for a wide range of demanding applications. Commonly used in X-ray equipment, radiation shielding, and other medical shielding solutions, Class 3 powder is a blend of pure tungsten (W) with a nickel (Ni) and iron (Fe) binder.

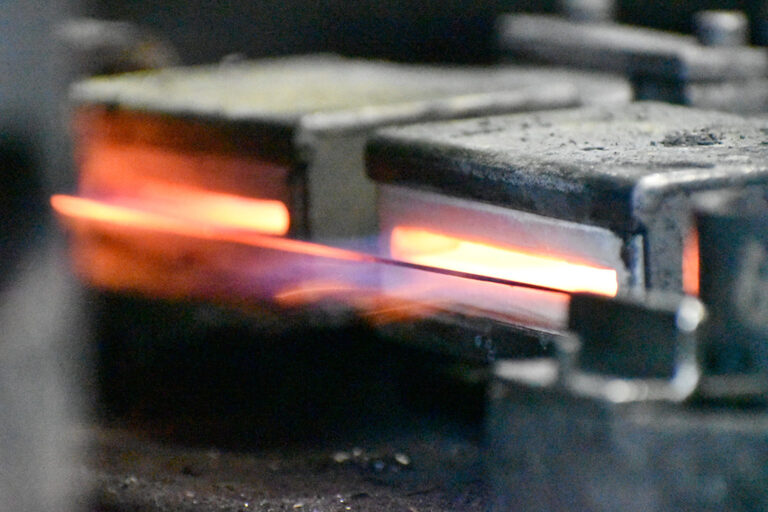

The manufacturing process involves pressing and sintering the Class 3 powder, with the option for additional machining to create high-quality tungsten heavy alloy (WHA) blocks, rods, or custom-shaped components. While Class 3 powder offers slightly lower density than pure tungsten or Class 4 materials, it remains significantly denser than Class 1 or Class 2 alternatives. To further enhance its performance, specialized post-sintering heat treatments can occur to help improve elongation and fracture resistance, making it a reliable and robust choice for critical applications.

ASTM B777 Class 3 Powder Benefits

ASTM B777 Class 3 powder is well-suited for applications that demand both low magnetic permeability and significant attenuation, making it an ideal material.

- Enhanced radiation shielding: It offers superior density and environmental benefits compared to lead, making it an excellent choice for radiation shielding.

- Versatility in demanding applications: With its high density, it excels in vibration-dampening and balance-weight applications.

- Defense-grade performance: Its unique combination of yield strength, elongation, and density makes it highly valuable for various defense applications.

- Superior gamma and x-ray absorption: Class 3 material exhibits an exceptional ability to absorb gamma rays and x-rays.

- Improved machinability: Compared to Class 4 or pure tungsten, it provides better machinability, making it easier to work with for precise applications.

Technical Data and SPecifications

| Grade | Units | K1800 | ET95 | K1801 | ET95NM |

| Tungsten content, Nominal | % | 95 | 95 |

| Density, Nominal | (g/cm3) | 18.0 | 18.0 |

| (lb/in3) | 0.65 | 0.65 | |

| Hardness | (Rc) | ≤ 34 | ≤ 34 |

| Ultimate Tensile Strength | (ksi) | ≥ 105 | ≥ 94 |

| (N/mm2) = Mpa | ≥ 724 | ≥ 648 | |

| Yield Strength | (ksi) | ≥ 75 | ≥ 75 |

| (N/mm2) = Mpa | ≥ 517 | ≥ 517 | |

| Elongation | (%) | ≥ 3 | ≥ 1 |

| Modulus of Elasticity | (psi x 106) | 48 | 45 |

| (kN/mm2) | 330 | 310 | |

| Magnetic Properties | slight | none | |

| Magnetic Permeability | (µ) | > 1.05 | ≤ 1.05 |

| Thermal Expansion Coefficient | (x10-6/K)(20°C-500°C) | 4.8 | 5 |

| Thermal Conductivity | (cgs) | 0.27 | 0.32 |

| Electrical Conductivity | (% IACS) | 15 | 16 |

| AMS-T-21014, MIL-T-210014 | Class 3 | Class 3 | |

| ASTM B777 | Class 3 | Class 3 | |

| AMS 7725 | Class 3 Type 2 | Class 3 Type 1 | |

| Nominal Chemical Composition | Ni content % Fe content % Cu content % Co content % W content % | 2.6 | 3.5 1.2 | 1.5 0.95 | – 0.21 | – 95.0 | 95.0 | 3.4 | 4.4 0.1 | 0.6 1.37 | – 0.01 | – 95.0 | 95.0 |

Elmet Technologies Commitment to Quality

Quality is at the core of everything we manufacture at Elmet Technologies. Our ASTM B777 Class 3 powder undergoes rigorous testing and inspection to meet or exceed ASTM B777 standards. We adhere to strict quality control processes and maintain ISO certification to ensure our products consistently perform, even in the most challenging environments. By choosing Elmet, you’re investing in unmatched quality, reliability, and performance.