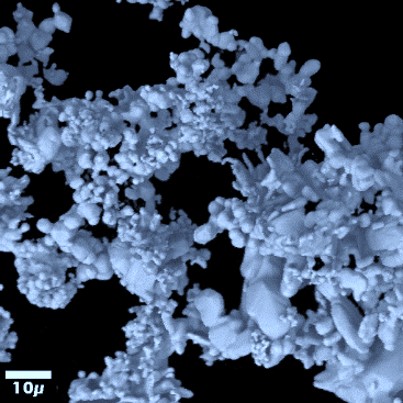

High-Purity Molybdenum Metal Powder

Elmet Technologies manufactures its high-purity molybdenum metal powder, MoMP, for pressing and sintering applications. As a high-performance powder of the highest purity, MoMP is a high-performance powder featuring exceptional properties, with consistent particle size distribution and enhanced flowability.

With high purity levels, MoMP ensures optimal mechanical properties, enabling precise control in component manufacturing. It is also utilized in propylene oxide catalysts and in the creation of MoSi2 for heating elements, offering broad utility and value in manufacturing. In addition, we offer a wide array of custom powders tailored to specific customer requirements. Contact the experts at Elmet Technologies to discuss your desired materials and powder metallurgy requirements.

High-Purity Molybdenum Metal Powder Applications

At Elmet Technologies, we engineer high-purity molybdenum metal powder to enhance manufacturing capabilities in pressing and sintering applications across a wide range of industries. MoMP is specifically designed to deliver exceptional performance in:

- Cold Isostatic Pressing (CIP) and sintering ingot production.

- Diamond drill bits as a matrix powder.

- Hardening alloys as an alloying addition.

With decades of expertise in powder metallurgy and refractory metal manufacturing, Elmet Technologies leverages the unique properties of molybdenum to produce high-performance components with superior heat resistance, strength, and durability.

Advanced Press and Sinter Process

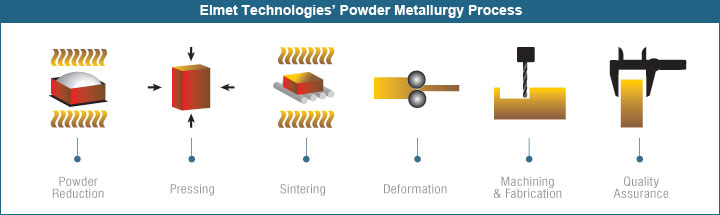

Elmet’s press and sinter process ensures precision and performance at every step:

- Powder Compaction: We compact molybdenum powder into a mold to form a “green” component, adding adhesives as needed for extra integrity.

- Stabilization: We stabilize the green component to preserve its shape and structure.

- Sintering: We use molybdenum’s high melting point and thermal conductivity to sinter the component, achieving optimal density and strength.

- Final Product: We produce a durable, high-performance component tailored to meet demanding applications.

High-Purity Molybdenum Powder Metallurgy Process

Chemical Characteristics of MoMP Powder

| Mo (excluding gases) | 99.95% min |

| O | 0.100% max |

| Cr | 0.005% max |

| Fe | 0.005% max |

| Mg | 0.001% max |

| Ni | 0.002% max |

| Si | 0.003% max |

| Sn | 0.003% max |

The Powder Metallurgy Experts

As a global leader in refractory metals, Elmet Technologies excels as a U.S. manufacturer of high-purity molybdenum metal powder by showcasing unparalleled application knowledge and technical expertise. Through advanced technology-driven manufacturing processes, we deliver high-performance solutions that meet the demands of our customers.

We custom-formulate molybdenum powders to meet your exact requirements. Our expertise includes developing diverse grain structures, adjusting green strengths, and optimizing particle sizes. These refined processes ensure our powders are perfect for your unique applications. Elmet consistently delivers innovative, high-quality refractory metals and advanced material solutions.