Lanthanated Molybdenum Powder

Elmet Technologies is a global leader in the manufacture of high-performance lanthanated molybdenum powder for demanding applications. With nearly 100 years of powder metallurgy expertise, Elmet Technologies has a longstanding history of transforming high-quality metal powders into a diverse range of premium products. Lanthanated molybdenum alloys exhibit great formability at all grade levels when compared to pure molybdenum in the same condition.

The material advantages of lanthanated molybdenum, like superior creep resistance, are only realized, if the material is recrystallized prior to use at high temperatures. For applications where high-temperature dimensional stability and sag resistance is paramount, for example setter tiles, sintering boats, and furnace elements, Lanthanated molybdenum provides superior performance. Start a discussion with our team of metallurgists today to learn more about our MoLa alloys.

Lanthanated Molybdenum Powder

Lanthanated molybdenum powder is a composite blend of molybdenum (Mo) and lanthanum oxide (La2O3). It offers significant advantages for high-temperature applications due to its exceptional mechanical and thermal properties. Unlike pure molybdenum, MoLa is engineered to exhibit enhanced strength, improved creep resistance, and elevated thermal conductivity. The addition of La2O3 increases the recrystallization temperature of MoLa, making it better suited for demanding environments than pure Mo or HCT Molybdenum.

Our Powder Metallurgy Techniques

Elmet Technologies specializes in manufacturing lanthanated molybdenum powder and refractory metal products using advanced powder metallurgy techniques. Our offerings include lanthanted molybdenum powders with lanthana content ranging from 0.3% to 1.1% by weight. For unique applications with custom requirements, our team of experts are available for discussion.

Lanthanated Molybdenum vs. Pure Molybdenum

- Higher creep resistance

- Higher strength in the 1000° to 1300°C range

- Higher recrystallization temperature

- Better ductility characteristics

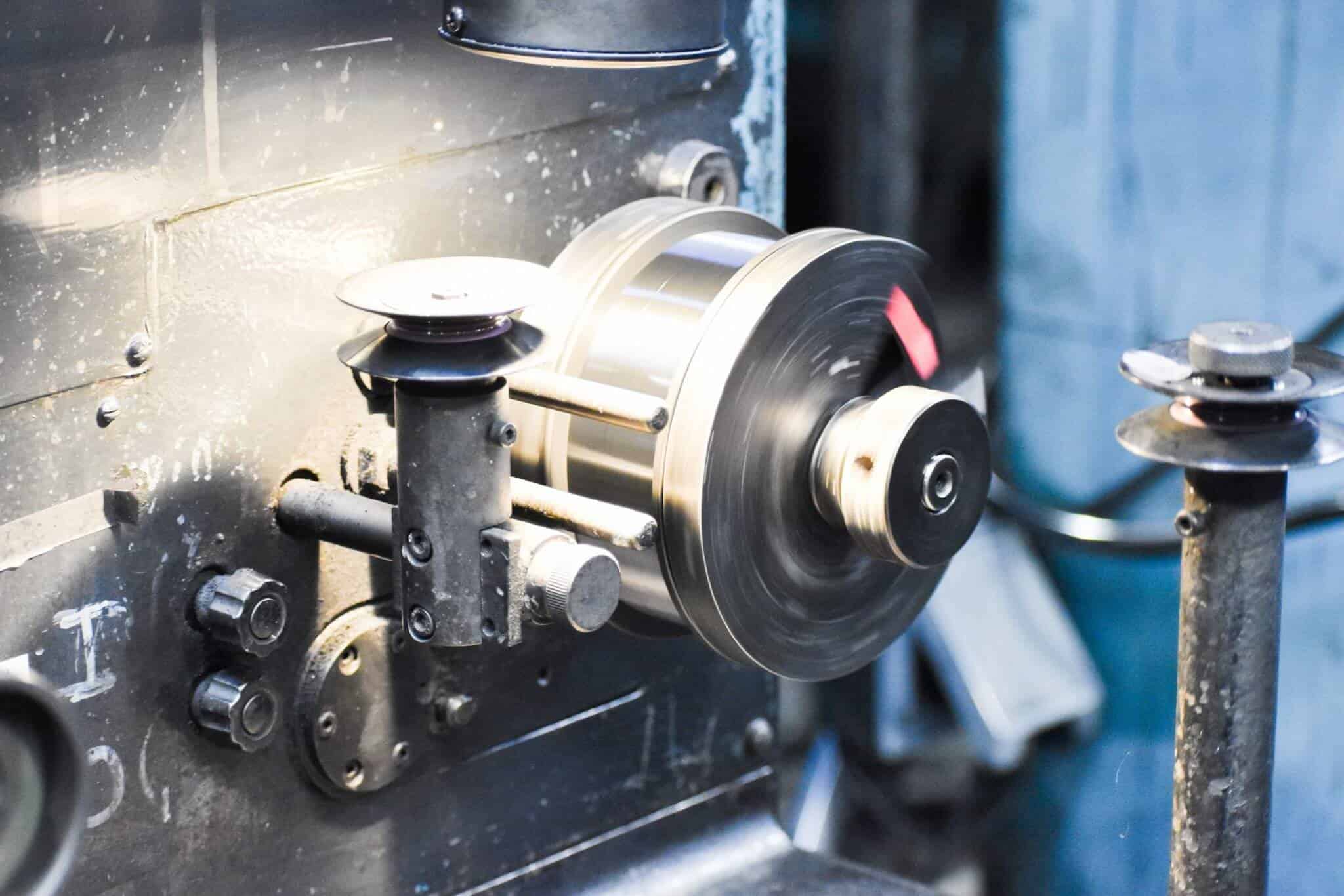

Precision Machining and Fabrication

Component and assembly specifications are becoming more demanding as technology advances. This requires machining and fabrication techniques to support complex geometries. At Elmet Technologies, we have decades of experience offering sophisticated lanthanated molybdenum machining and fabrication capabilities. We operate more than 70 machines dedicated to supporting strict precision machining and fabrication requirements.

Common Lanthanted Molybdenum Products:

- Furnace components

- Complex assembled products

- Long products: rod and bar

- Flat products: sheet and plate